TM 5-3805-293-23-2

0027

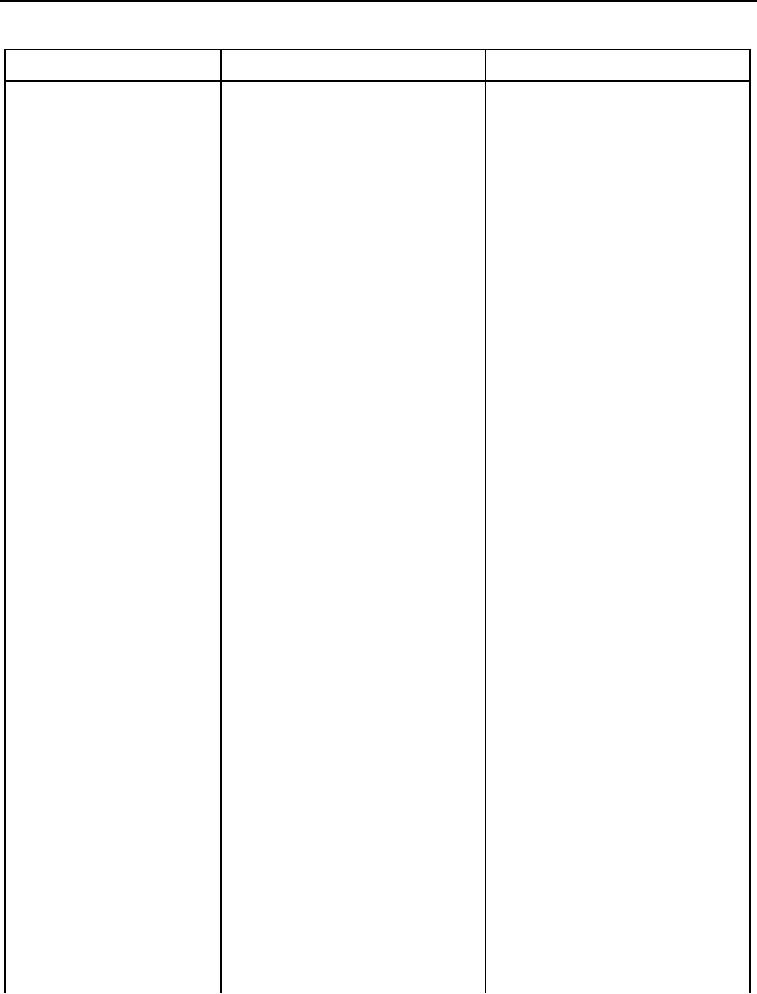

Table 1. Implement Code (0615-02 TO 2113-04) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0650-02 Implement 2 ECM

2. Disconnect cab lower wiring har-

Harness Code Data Erratic,

ness connector P-C93 (WP 0009,

Intermittent or Incorrect

Figure 163) from messenger (WP

Data - Continued

0009, Figure 164) (WP 0272).

3. Turn battery disconnect switch

and ignition switch to the ON posi-

tion (TM 5-3805-293-10).

4. Using digital multimeter, test for

Voltage Within 18 to 26 Volts -

voltage between harness connec-

Proceed to step 5.

tor P-C93 (WP 0009, Figure 163)

Voltage Less Than 18 Volts -

terminal 1 and machine ground.

Replace cab lower wiring harness

Voltage should be 18 to 26 volts.

(WP 0266).

Proceed to step 8.

5. Using digital multimeter, test for

Voltage Within 18 to 26 Volts -

voltage between harness connec-

Proceed to step 6.

tor P-C93 (WP 0009, Figure 163)

Voltage Less Than 18 Volts -

terminal 3 and machine ground.

Replace cab lower wiring harness

Voltage should be 18 to 26 volts.

(WP 0266).

Proceed to step 8.

6. Turn ignition switch and battery

disconnect switch to the OFF

position (TM 5-3805-293-10).

7. Using digital multimeter, test for

Resistance 5.0 Ohms or Less -

continuity between harness con-

Proceed to Test Step 3.

nector P-C93 (WP 0009, Figure

Resistance More Than 5.0 Ohms -

163) terminal 2 and machine

Replace cab lower wiring harness

ground.

(WP 0266).

Resistance should be less than

Proceed to step 8.

5.0 ohms.

8. Using MSD (WP 0006), select

0650-02 Code Remains Active -

Implement 120M and verify 0650- Repeat troubleshooting from the

02 is not active.

beginning of this diagnostic code.

0650-02 Code Not Active -

Troubleshooting complete.

Test Step 3. Test Data Link Circuit.

1. Disconnect harness connector

FA-C20 (WP 0009, Figure 113)

from transmission ECM J1 (WP

0009, Figure 112).

2. Remove rear bulkhead cover

plate (WP 0266) from rear of cab.

0027-37