TM 5-3805-293-23-2

0027

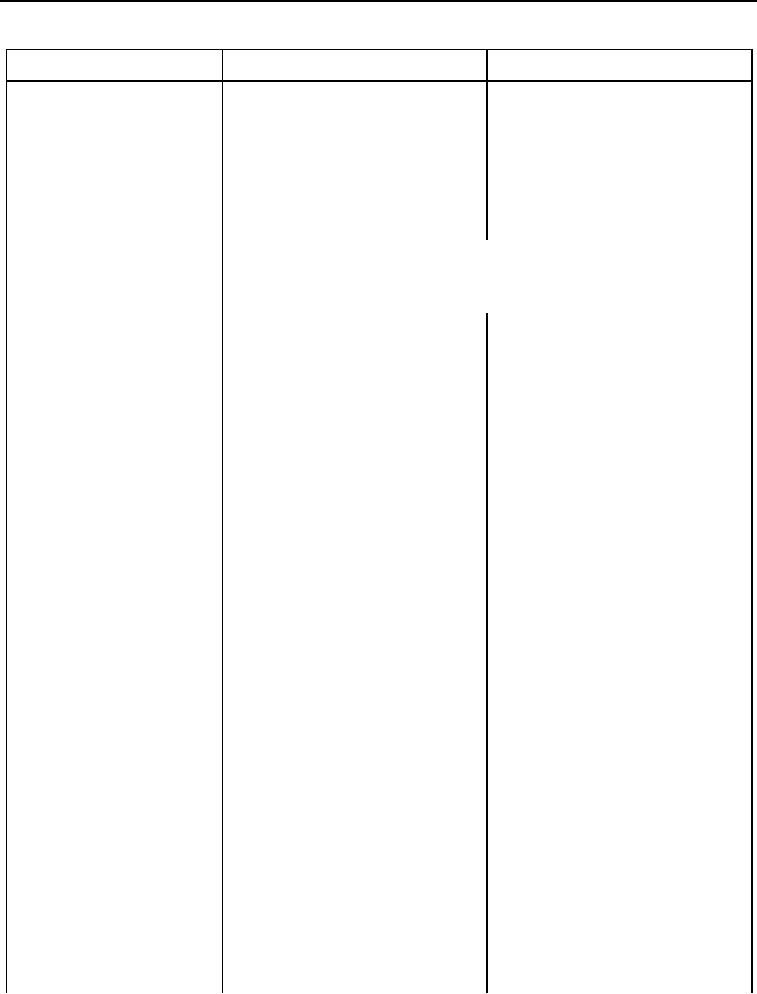

Table 1. Implement Code (0615-02 TO 2113-04) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0615-03 Machine Articula-

4. Using digital multimeter, test for

Voltage 7.5 to 8.5 Volts - Proceed to

tion Angle Sensor Voltage

voltage between harness connec-

Test Step 4.

Above Normal - Continued

tor AT-C3 (WP 0009, Figure 144)

Voltage Less Than 7.5 Volts -

terminal A and machine ground.

Proceed to step 5.

Voltage should be 7.5 to 8.5 volts.

5. Turn ignition switch and battery

disconnect switch to the OFF

position (TM 5-3805-293-10).

N OT E

Harness connector is located behind cab bulkhead cover on right rear

of cab.

6. Remove rear bulkhead cover

plate (WP 0266).

7. Disconnect rear chassis wiring

harness connector FA-C23 (WP

0009, Figure 17) from cab lower

wiring harness connector P-C71

(WP 0009, Figure 18).

8. Disconnect cab lower wiring har-

ness connector P-C41 (WP 0009,

Figure 68) from Implement 1 ECM

J1 (WP 0009, Figure 69) (WP

0268).

9. Using digital multimeter, test for

Resistance 5.0 Ohms or Less -

continuity between harness con-

Proceed to step 10.

nector P-C41 (WP 0009, Figure

Resistance More Than 5.0 Ohms -

68) terminal 44 and harness con-

Replace cab lower wiring harness

nector P-C71 (WP 0009, Figure

(WP 0266).

18) terminal 19.

Connect secondary steering harness

Resistance should be less than

connector AT-C3 (WP 0009, Figure

5.0 ohms.

144) to left articulation angle position

sensor (WP 0009, Figure 145) (WP

0257).

Proceed to step 12.

10. Disconnect rear chassis wiring

harness connector FA-C5 (WP

0009, Figure 111) from second-

ary steering wiring harness AT-C1

(WP 0009, Figure 110) (WP

0186).

0027-14