TM 5-3805-293-23-2

0027

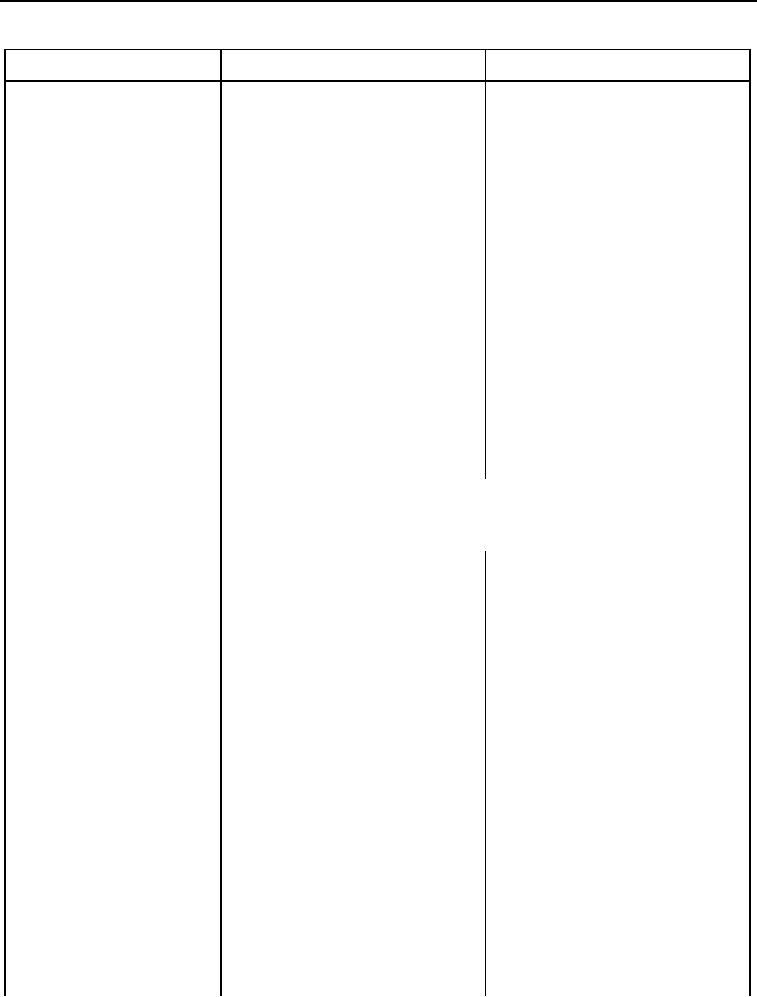

Table 1. Implement Code (0615-02 TO 2113-04) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0615-02 Machine Articula-

4.

Using digital multimeter, test for

Resistance 5.0 Ohms or Less -

tion Angle Sensor Data

continuity between harness con-

Replace articulation angle sensor 1

Erratic, Intermittent or Incor-

nector P-C41 (WP 0009, Figure

(left) (WP 0257).

rect - Continued

68) terminal 45 and harness con-

Connect rear chassis wiring harness

nector P-C39 (WP 0009, Figure

connector FA-C23 (WP 0009, Figure

70) terminal 41.

17) to cab lower wiring harness

Resistance should be less than

connector P-C71 (WP 0009, Figure

5.0 ohms.

18) (WP 0188).

Connect cab lower wiring harness

connector P-C41 (WP 0009, Figure

68) to Implement 1 ECM J1 (WP

0009, Figure 69) (WP 0268).

Connect cab lower wiring harness cab

lower wiring harness connector P-C39

(WP 0009, Figure 70) to Implement 1

ECM J2 (WP 0009, Figure 71) (WP

0268).

Proceed to step 19.

Resistance More Than 5.0 Ohms -

Proceed to step 5.

N OT E

Harness connector is located behind cab bulkhead cover on right rear

of cab.

5. Remove rear bulkhead cover

plate (WP 0266).

6. Disconnect rear chassis wiring

harness connector FA-C22 (WP

0009, Figure 47) from cab lower

wiring harness connector P-C69

(WP 0009, Figure 46) (WP 0188).

7. Using digital multimeter, test for

Resistance 5.0 Ohms or Less -

continuity between harness con-

Proceed to step 8.

nector P-C69 (WP 0009, Figure

Resistance More Than 5.0 Ohms -

46) terminal 26 and harness con-

Replace cab lower wiring harness

nector P-C39 (WP 0009, Figure

(WP 0188).

70) terminal 41.

Connect harness connector P-C39

Resistance should be less than

(WP 0009, Figure 70) to Implement 1

5.0 ohms.

ECM J2 (WP 0009, Figure 71) (WP

0268).

Proceed to step 19.

8. Disconnect harness connector

FA-C21 (WP 0009, Figure 124)

from transmission ECM J2 (WP

0009, Figure 112).

0027-9