TM 5-3805-261-34

FUEL SYSTEM MAINTENANCE. (cont)

3-25.

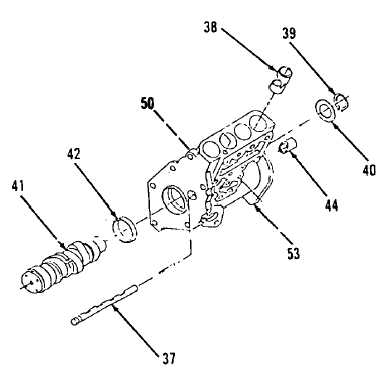

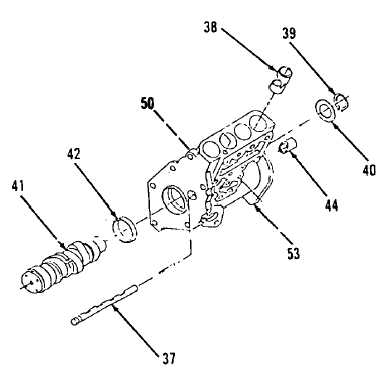

Fuel Injection Pump. (Sheet 11 of 16)

ASSEMBLY (cont)

10. Using clean oil, lubricate

camshaft (41) and install.

11. Position housing (53). Stand

camshaft (41) on end of housing

(53). Do not allow camshaft (41)

to fall. Install a wood block

under camshaft (41).

12. Position washer (40) over end of

camshaft (41).

13. Using sleeve and suitable driver

and hammer, install washer (40)

on camshaft (41). Camshaft (41)

must have 0.0112 + 0.0093 inch

end play after assembly.

14. Using snap ring pliers, install

ring (39) in groove in end of

camshaft (41).

15. Using clean oil, lubricate four

lifters (38).

16. Using magnet, install four

lifters (38). Do not drop four

lifters (38) into place. Aline

grooves in four lifters (38) with

pin (50, Figure 3-91).

17. Install rack (37) through rear of

new bearing (43) alining notch in

new bearing (44) with the spline

on rack (37).

18. Install timing pin to center of

rack (37).

Go to Sheet 12

3-126

Figure 3-91.