TM 5-3805-261-34

FUEL SYSTEM MAINTENANCE. (cont)

3-25.

Fuel Injection Pump. (Sheet 13 of 16)

ASSEMBLY (cont)

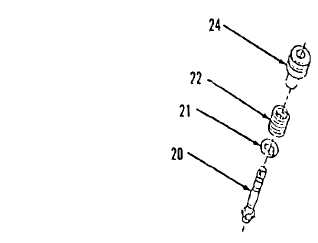

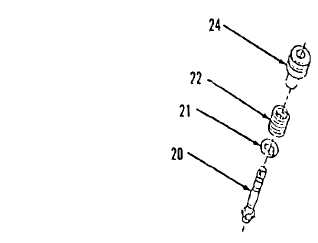

27. Position washer (21) on plunger

assembly (20) with flat side of

washer facing gear on plunger

assembly (20).

28. Install plunger assembly (20)

through spring (22) and into

barrel (24) until washer (21)

engages spring (22).

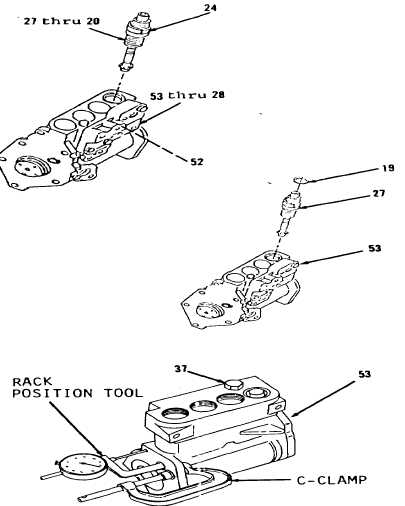

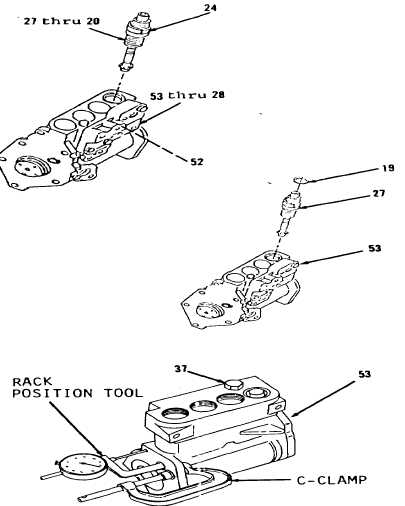

29. Aline items 27 thru 20 as an

assembly with slot in gear on

items 53 thru 28 180 degrees away

from groove in barrel (24, Figure

3-95).

30. Using extractor, aline groove in

barrel (24) with dowel (52) in

housing (53) and install.

Installation of remaining pump

assemblies is the same.

NOTE

Installation of pump assembly

is made easier by rotation of

camshaft lobe away from four

lifters.

31. Install new preformed packing

(19) on top of bonnet (27, Figure

3-88).

32. Measure rack (37, Figure 3-96)

travel. Install rack position

tools, contact pin and C-clamp.

Correct rack travel is 0.618

inch. A smaller measurement is

an indication of wrong

installation of items 27 thru 20.

Remove tooling and install

remaining items.

Go to Sheet 14

3-128

Figure 3-89.

Figure 3-95.

Figure 3-88.

Figure 3-96.