TM 5-3805-261-34

FUEL SYSTEM MAINTENANCE.

3-25.

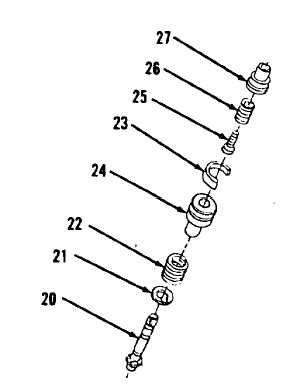

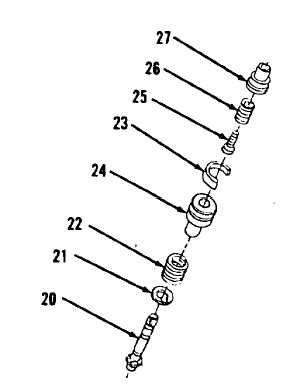

Fuel Injection Pump. (Sheet 6 of 16)

DISASSEMBLY

CAUTION

Use extreme care not to

damage the injection pumps or

components. Any scratches to

the surfaces of the plungers,

barrels and bonnets will

cause leakage inside the fuel

injection pump. The plunger

and barrel for each pump are

made as a set. Do not put

the plunger of one pump in

the barrel of another pump.

Do not mix components from

fuel injection pump

assemblies.

7.

Remove plunger assembly (20) out

of spring (22) and barrel (24,

Figure 3-89).

8.

Remove spring seat (21) from

plunger assembly (20).

NOTE

Do not remove the gear from

plunger assembly. The gear

and plunger are assembled and

adjusted at the factory.

9.

Remove spring (22) from barrel

(24).

10. Hold barrel (24) and bonnet (27)

together.

11. Remove ring (23).

12. Separate barrel (24) and bonnet

(27).

13. Remove check (25) and spring (26)

from bonnet (27). Do not dis-

assemble check (25).

Go to Sheet 7

3-121

Figure 3-89.