TM 5-3805-261-34

FUEL SYSTEM MAINTENANCE.

3-25.

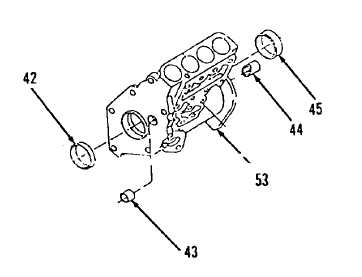

Fuel Injection Pump. (Sheet 10 of 16)

ASSEMBLY

6.

Using suitable driver and hammer,

install bearing (45, Figure

3-91), if removed. Position new

bearing (45) with joint in new

bearing (45) pointing straight up

at top of housing (53). Drive

new bearing (45) to a depth of

0.039 inch below surface of

housing (53).

7.

Install new bearing (44), if

removed. Install locator plate,

alining scribed marks and

securing the plate to housing

(53) with attaching plate bolts.

Use clean grease to hold new

bearing (44) on the end of driver

in locator plate, with the groove

in the driver in alinement with

the pin in the locator plate.

Use a hammer to tap new bearing

(44) until shoulder of driver is

against locator plate. Remove

locator plate.

8.

Using a suitable driver and

hammer, install new bearing (43),

if removed, to a depth of 0.282

inch below surface of housing

(53).

9.

Using a suitable driver and

hammer, install new bearing (42),

if removed. Position new bearing

(42) with joint in new bearing

(42) pointing straight up toward

top of housing (53) and install

new bearing (42) 0.010 inch below

surface of housing (53).

Go to Sheet 11

3-125

Figure 3-91.