TM 5-3805-293-23-2

0032

FLYWHEEL, FLYWHEEL HOUSING AND GEAR GROUP INSPECT CONTINUED

Gear Group

00032

N OT E

Inspect gears for wear or for damage.

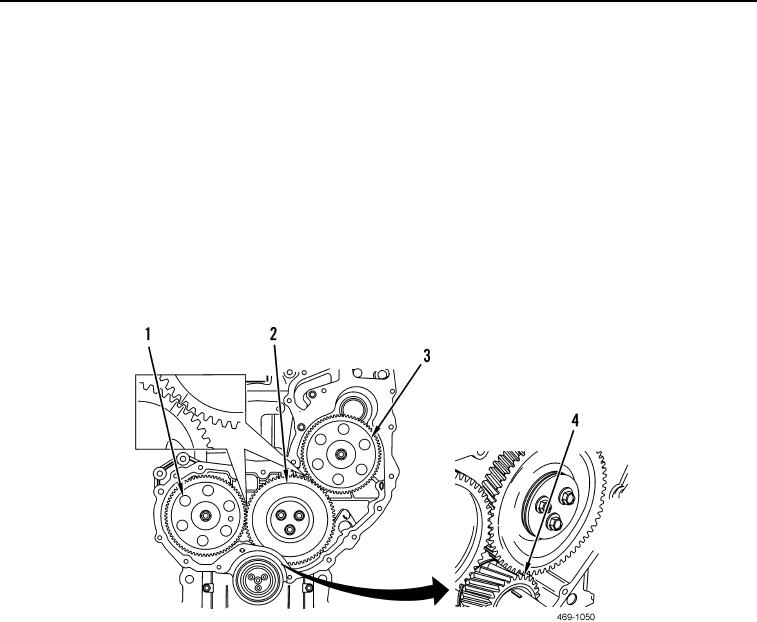

1. Measure backlash between camshaft gear (Figure 33, Item 1) and idler gear (Figure 33, Item 2). Required

backlash 0.0020 in to 0.0055 (0.05 to 0.14 mm).

2. Measure backlash between idler gear (Figure 33, Item 2) and crankshaft gear (Figure 33, Item 4). Required

backlash 0.0020 in to 0.006 (0.05 to 0.15 mm).

3. Measure backlash between fuel injection pump gear (Figure 33, Item 3) and idler gear (Figure 33, Item 2).

Required backlash 0.0020 in to 0.0059 (0.05 to 0.15 mm).

4. Measure end play on idler gear (Figure 33, Item 2).

Figure 33. Gear Inspection and Backlash.

032

END OF TASK

DRIVE BELT INSPECTION, PULLEY AND VIBRATION DAMPER INSPECTION, AND BELT TENSIONER

CHECK

N OT E

Engine is equipped with an automatic belt tensioner. Manual adjustment of belt is not

required.

If new belt is installed, re-inspect belt after 30 minutes of operation.

Drive Belt Inspection

00032

1. Remove drive belt (WP 0093) from machine.

2. Inspect drive belt for stretching, damage, glazing, wear, and for more than four cracks per inch (25.4 mm).

a. Replace drive belt if damaged, cracked, stretched, glazed, or worn (WP 0093).

b. Drive belt OK, proceed to Pulley and Vibration Damper Inspection in this work package.

Change 1