TM 5-3805-293-23-2

0033

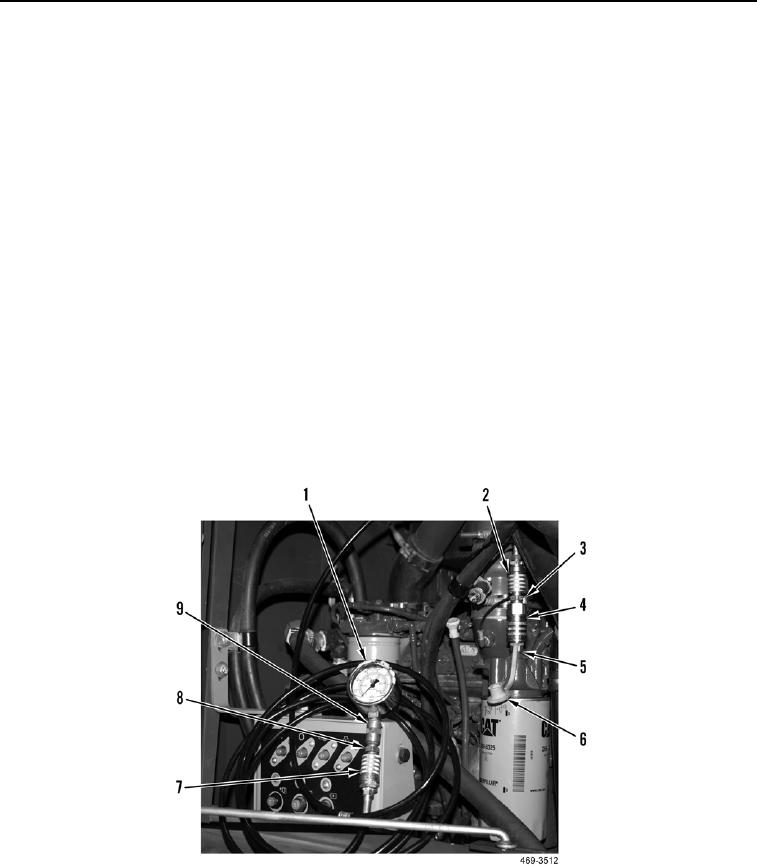

ENGINE OIL PRESSURE TEST CONTINUED

1. Replace engine oil filter (WP 0087).

2. Remove dust cap (Figure 1, Item 6) from oil sample port (Figure 1, Item 5).

3. Install coupling (1/4 inch 18 NPTF) (Figure 1, Item 4), coupling (1/4 inch NPT - External Nipple) (Figure 1,

Item 3), and hose (Figure 1, Item 2) on oil sample port (Figure 1, Item 5).

4. Install pipe coupling (1/4 inch NPT) (Figure 1, Item 9), and coupling (1/4 inch NPT - External Nipple) (Figure 1,

Item 8) on gauge (Figure 1, Item 1).

5. Install gauge (Figure 1, Item 1) on hose (Figure 1, Item 7) from Dial Indicating Pressure Gauge Kit.

6. Start engine (TM 5-3805-293-10), and allow engine coolant to reach 160 - 180 F (71.1 - 82.2C). Refer to How

to Use On-Board Diagnostics (WP 0005) to view engine coolant temperature using the messenger.

7. With assistance, observe and record pressure on gauge: minimum oil pressure should be at least 45 psi (310

kPa) with throttle fully depressed. Normal engine oil pressure operates between 37 psi (255 kPa) and 85 psi

(586 kPa).

a. If oil pressure is lower than 45 psi (310 kPa) with throttle fully depressed, return to troubleshooting.

b. If oil pressure is lower than 37 psi (255 kPa) at any time, replace oil pump (WP 0092).

c.

If oil pressure is greater than 85 psi (586 kPa), replace oil pump (WP 0092).

8. Turn ignition switch and battery disconnect switch to the OFF position (TM 5-3805-293-10).

9. Remove hose coupling (Figure 1, Item 2), coupling (1/4 inch NPT - External Nipple) (Figure 1, Item 3),

coupling (1/4 inch 18 NPTF) (Figure 1, Item 4) from oil sample port (Figure 1, Item 5).

10. Install dust cap (Figure 1, Item 6) on oil sample port (Figure 1, Item 5).

Figure 1. Oil Pressure Test Port and Gauge.

0033

END OF TASK