TM 5-3805-263-14&P-3

DISASSEMBLY AND ASSEMBLY

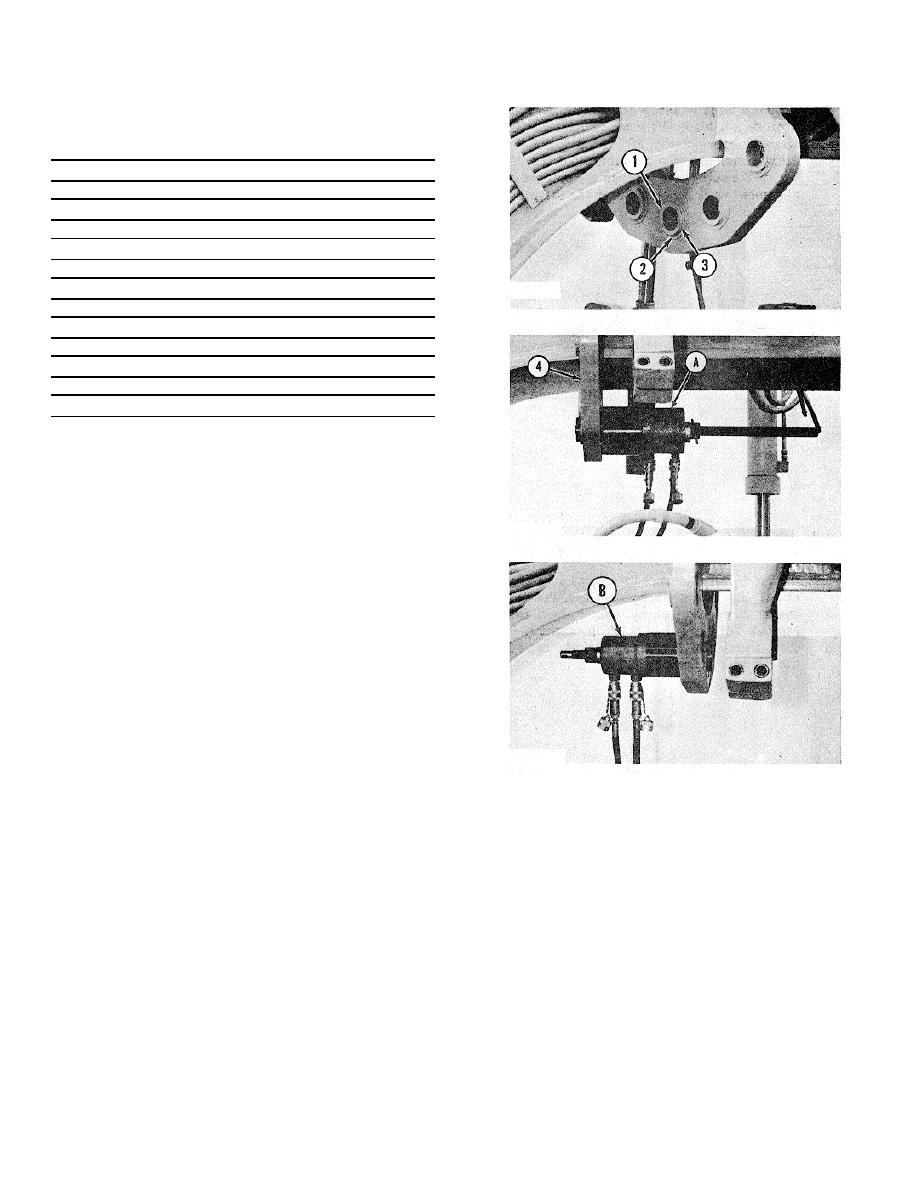

CENTERSHIFT LOCKPLATE BUSHINGS

REPLACE CENTERSHIFT

LOCKPLATE BUSHING

Tools Needed

A

B

1P1832

Pulling Adapter

1

9S5558

Stud

1

1P544

Nut

1

3H467

Washer

1

5P3100

Pump Group (or electric)

1

1

9S9147

Installer Ring

1

7F9540

Puller Assembly

1

1

5F7353

Washer

1

5F7351

Nut

1

5P4776

Stud

1

5P4749

Adapter

1

9S8537

Installer Ring

1

start by:

a) remove blade shift bar

NOTE: Before disassembly check the clearance between

the snap ring on bushing and the shims. On the earlier

models the maximum clearance will be approximately

.014 in. (.356 mm). On the later models the maximum

clearance will be .350 in. (8.89 mm) between the snap

ring and shims.

1. Remove snap ring (2) and shims (3) from

bushings (1).

2. Remove the bushings from lockplate (4)

toward the front of the machine with tooling (A).

3. Lower the temperature of the new bushings for

the earlier models to -70 to -900F (-57 to -

680C) on the later models lower the

temperature to -6 to -260F (-21 to -320C).

Install the bushing in the lockplate with tooling

(B). Install the bushing so it makes contact with

the shoulder in the lockplate.

4. Install the shims and the snap ring on the

bushing. The shims are used to get a .014 in.

(0.36 mm) maximum clearance between the

snap ring and lockplate on the earlier model

and a .350 in. (8.89 mm) maximum clearance

on the later models between the snap ring and

lock-plate.

NOTE: Some lockplate bushings can have replacements

made with the blade lift bar in position on the machine. It

will be necessary to put the blade lift bar and centershift

lock in a position away from the bushing of which a

replacement is to be made. end by:

a) install blade lift bar

3-200