TM 5-3805-261-34

TRANSMISSION MAINTENANCE.

14-2.

Transmission Assembly.

ASSEMBLY

33.

Using dry ice, lower temperature

of three bearing cups (39, Figure

14-26).

34.

Install three bearing cups (39).

35.

Install two carrier rings (37),

new seal rings (38) and snap

rings (36).

36.

Tilt and install items 46 thru 40

as an assembly.

37.

Install plug (49), two dowel pins

(48) and dowel pins (47) in

transmission housing.

NOTE

The following is a mainte-

nance procedure for the

installation of the forward

directional clutch. The

maintenance procedure for the

reverse directional clutch is

identical.

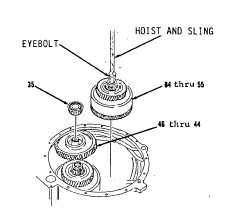

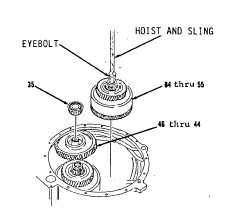

38.

Install 3/4-10NC forged eyebolt

in items 84 thru 55 as an

assembly (Figure 14-9).

39.

Lift items 46 thru 44 as an

assembly.

40.

Using hoist and sling, install

items 84 thru 55 as an assembly.

41.

Remove hoist and sling.

42.

Remove 3/4-10NC forged eyebolt.

43.

Heat roller bearing (35) in

engine oil SAE 30 to temperature

of 275 degrees F.

44.

Install roller bearing (35).

Go to Sheet 16

Figure 14-26.

Figure 14-9.

14-17