TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE.

10-17.

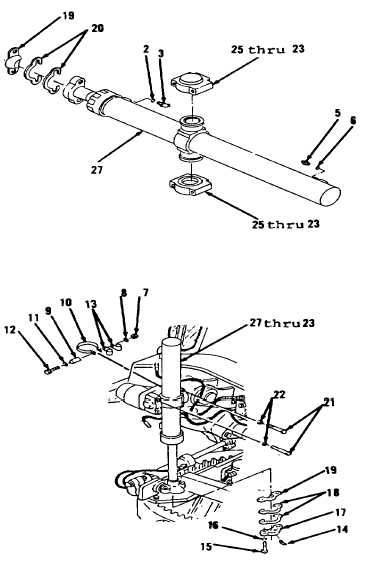

Blade Lift Cylinder. (Sheet 5 of 6)

INSTALLATION

5.

Position items 25 thru 23 as an

assembly on cylinder (27, Figure

10-134).

6.

Install new performed packing

(6), elbow (5), new preformed

packing (3) and connector (2) on

cylinder (27).

7.

Attach hoist and sling to

cylinder (27).

8.

Lubricate ballstud and two

inserts (19) with clean grease

after surfaces are wiped cleaned.

9.

Install two shim(s) (20) and one

of two inserts (19) on cylinder

(27).

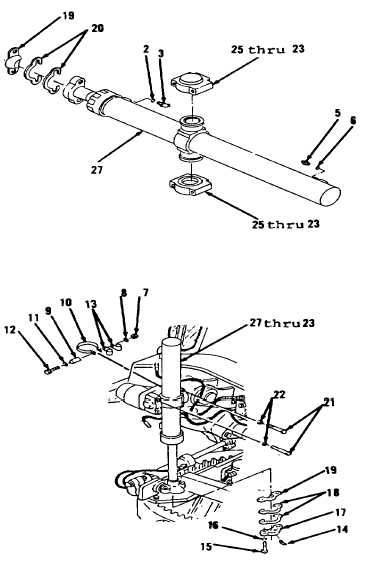

10.

Using hoist and sling, position

items 27 thru 23 as an assembly

(Figure 10-135).

11.

Install one of two inserts (19),

two shim(s) (18), cap (17), two

lockwashers (16), bolts (15) and

fitting (14).

12.

Check ballstud and two inserts

(19) for excessive clearance

between ballstud and surrounding

parts by moving cylinder assembly

(27). If ballstud or two inserts

(19) have become sufficiently

worn, excessive clearance may be

seen between ballstud and

surrounding parts. One or more

shim(s) (18 or 20) may be removed

to reduce unwanted clearance.

When removing two shim(s) (18 or

20), remove one shim from each

side of ballstud.

13.

Install four washers (22) and

bolts (21) in two caps (23).

Tighten four bolts (21) to 95

ft-lb torque.

Figure 10-135.

Figure 10-134.

Go to Sheet 6

10-101