TM 5-3805-261-10

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

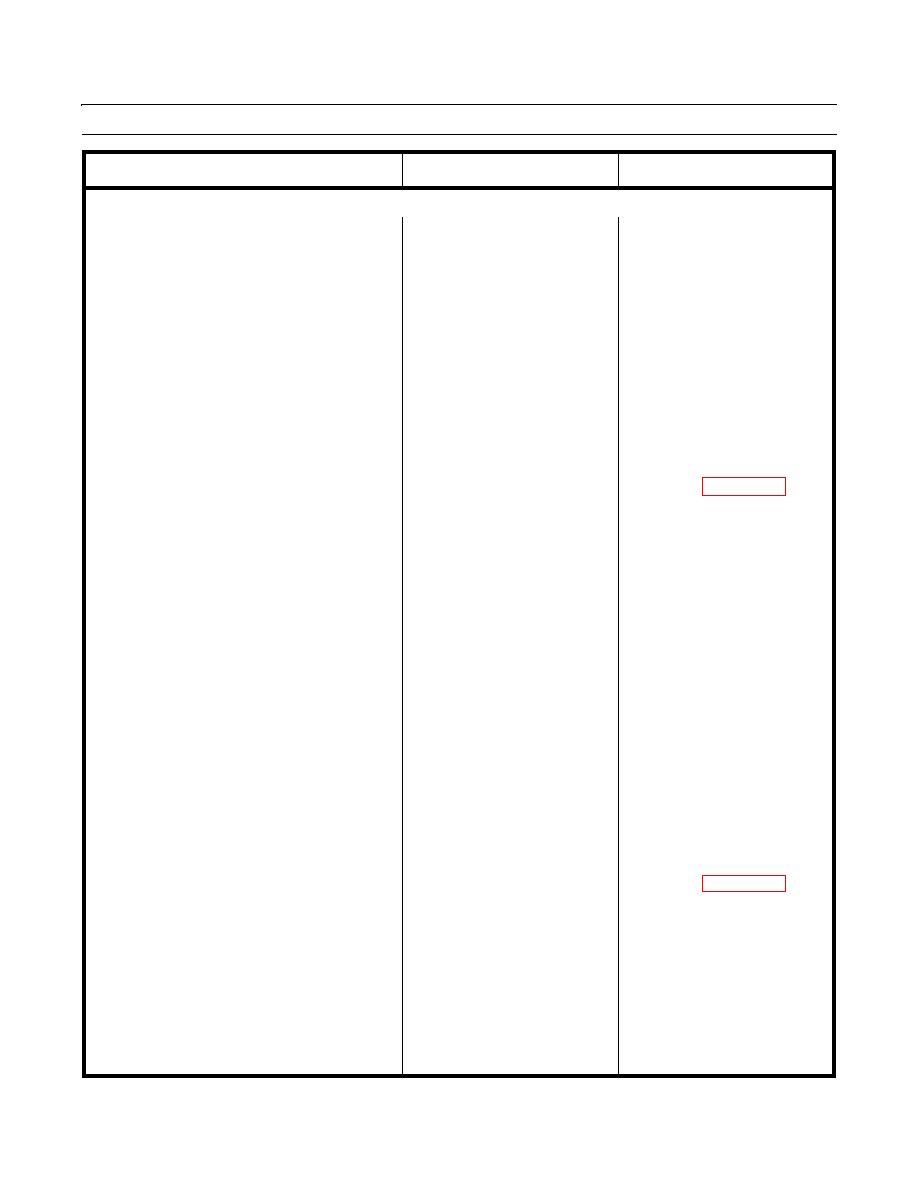

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

HYDRAULIC SYSTEM - CONTINUED

1. Check blade hydraulic lift

If any damage is found, notify

2.

Blade Drifts After Control Lever Is

cylinders for damage.

Unit Maintenance. If no damage

Released or Centered.

is found and problem still exists,

go to test step 2.

Clean any debris. If any damage

2. Check control linkage for

is found, notify Unit

damage or debris that would

Maintenance.

restrict freedom of movement

and/or automatic return to hold

position.

Clean any debris from

1. Check blade hydraulic lift

3.

Travel Time of Blade Lift Cylinders Is

cylinder(s). If problem still

cylinders for any buildup of

Excessively Slow.

exists, go to test step 2.

debris.

2. Check hydraulic oil level.

If hydraulic oil level is low, fill to

correct level (WP 0013 00). If

problem still exists, go to test step

3.

Clean any debris from linkage. If

3. Check control linkage for

any damage is found, notify Unit

damage or debris that would

Maintenance.

restrict freedom of movement

and/or automatic return to hold

position.

1. Check for bent or damaged

If lever is bent or damaged, notify

4.

Scarifier Control Lever Binds.

lever.

Unit Maintenance. If lever is

okay, go to test step 2.

Clean any debris from linkage. If

2. Check control linkage for

any damage is found, notify Unit

damage or debris that would

Maintenance.

restrict freedom of movement

and/or automatic return to hold

position.

1. Check scarifier area for any

Clean any debris from scarifier

5.

Travel Time of Scarifier Is Excessively

buildup of debris.

area. If problem still exists, go to

Slow.

test step 2.

2. Check hydraulic oil level.

If hydraulic oil level is low, fill to

correct level (WP 0013 00). If

problem still exists, go to test step

3.

Clean any debris from linkage. If

3. Check control linkage for

damage or debris that would

any damage is found, notify Unit

restrict freedom of movement

Maintenance.

and/or automatic return to hold

position.