TM 5-3805-261-10

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

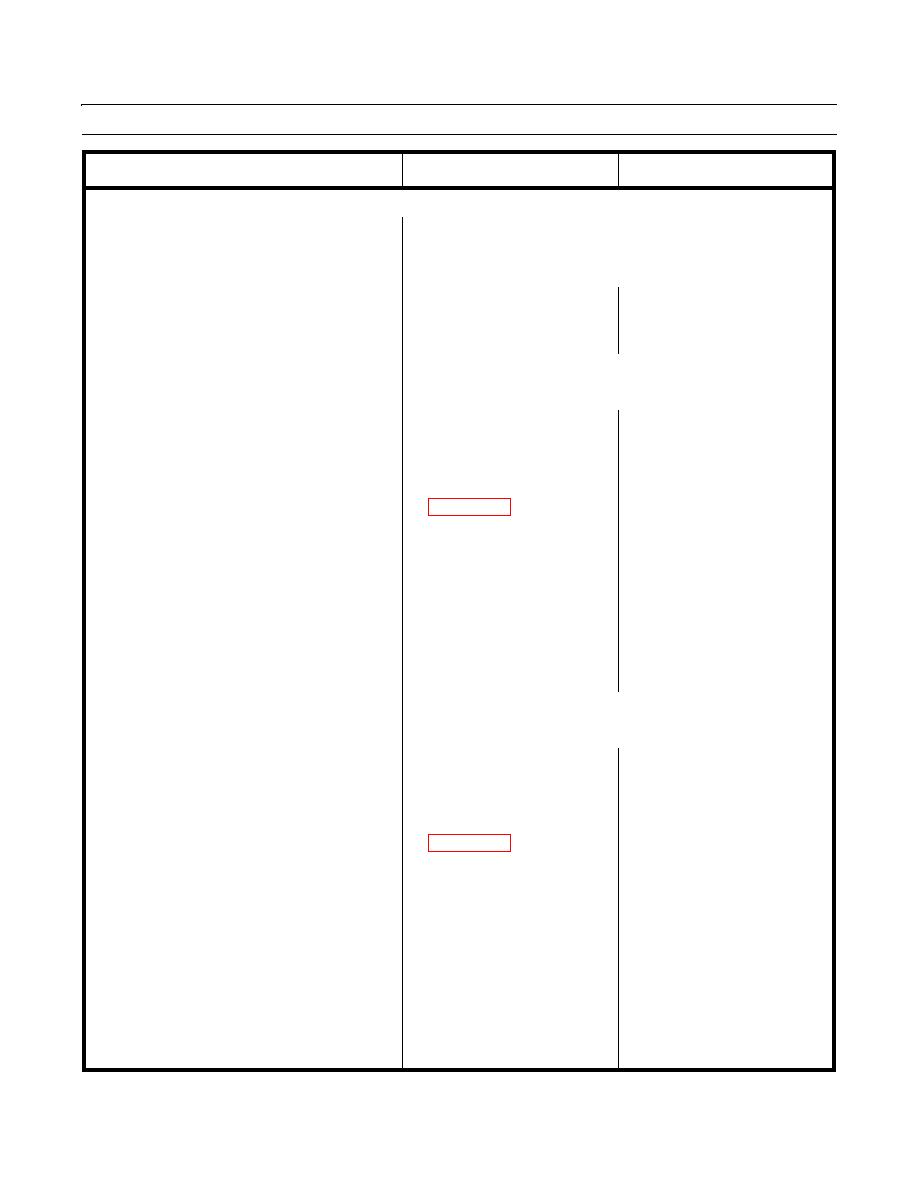

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

AIR SYSTEM AND BRAKES

WARNING

1.

Parking/Emergency Brake Will Not

Engage.

Park machine on level ground, stop engine, and lower blade to

prevent injury to operator and/or severe damage to machine.

1. Check for debris/obstruction at

Clean debris/obstruction from

brake actuator.

brake actuator. If problem still

exists, go to test step 2.

NOTE

Raise blade and scarifier before moving machine.

2. Slowly try to move machine

If problem still exists, go to test

forward to test if brake is

step 3.

engaged.

3. Perform parking brake test

If problem still exists, notify Unit

Maintenance.

1. Observe air pressure gages.

If air pressure is not above 60 psi

2.

Parking/Emergency Brake Will Not

Air pressure must be above 60

(414 kPa), check and close air

Release.

psi (414 kPa) in order to

tank drain valve(s) if required. If

release parking brake.

problem still exists, go to test step

2.

If any leaks are present, notify

2. Check for air leaks at air tank,

hoses, fittings, lines, and air

Unit Maintenance. If no leaks are

dryer (if equipped).

found, go to test step 3.

NOTE

Raise blade and scarifier before moving machine.

3. Slowly try to move machine

If problem still exists, notify Unit

forward to test if brake is

Maintenance.

released.

4. Perform parking brake test

If problem still exists, notify Unit

Maintenance.