TM 5-3805-261-10

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

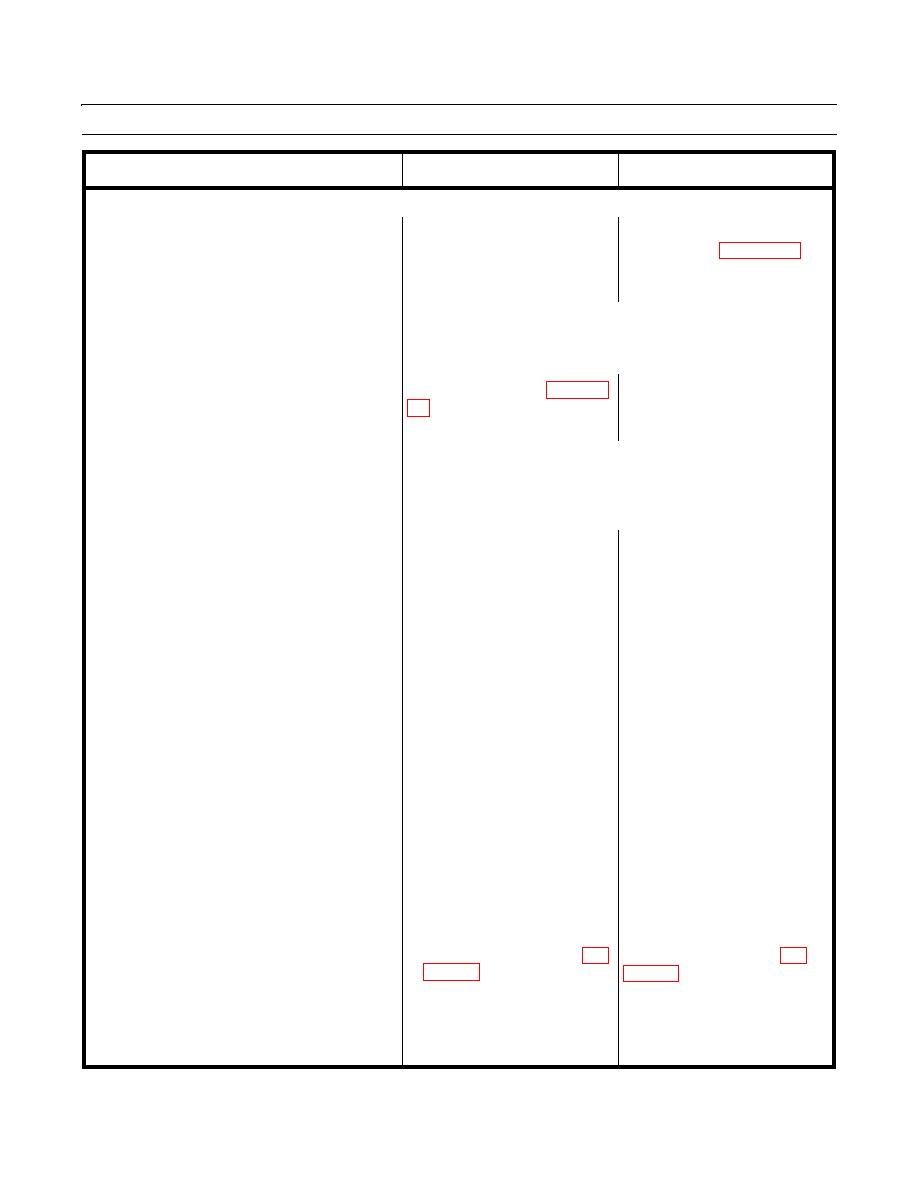

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

EMS FAULT INDICATORS - CONTINUED

8. Check transmission oil level.

If transmission oil level is low, fill

1.

EMS Coolant Temp Indicator Flashes

to correct level (WP 0013 00). If

During Operation - Continued.

level is okay and problem still

exists, notify Unit Maintenance.

CAUTION

2.

EMS Engine Oil Press (psi) Indicator

Flashes During Operation.

When engine oil pressure indicator flashes, immediate shut-

down of machine is required to prevent damage to machine.

Check engine oil level (WP 0013

If engine oil is low, fill to correct

level. If problem still exists,

notify Unit Maintenance.

WARNING

3.

EMS Brake Press (psi) Indicator Flashes

During Operation.

When brake air pressure low indicator comes on, bring machine

to a safe stop. Failure to follow this warning may result in

injury.

1. Ensure that air tank drain

Close drain valve(s) if required. If

valve(s) are closed.

problem still exists, go to test step

2.

If any leaks are present or if

2. Check for air leaks at air tank,

hoses, fittings, lines, and air

problem still exists, notify Unit

dryer (if equipped).

Maintenance.

1. Check for flashing hydraulic

Reduce load and continue to

4.

EMS Hydraulic Oil Temp Indicator

oil temp indicator during

monitor temperature. If indicator

Flashes During Operation.

operation.

is still flashing, go to test step 2.

If problem still exists, shut down

2. Allow engine to idle at 960

RPM for 5-10 minutes to cool

engine and go to test step 3.

down.

3. Check radiator for debris.

Remove debris. If there is

excessive debris, notify Unit

Maintenance. If no debris is

present, go to test step 4.

4. Check system for leaks.

If leaks are found, notify Unit

Maintenance. If no leaks are

found, go to test step 5.

5. Check hydraulic oil level (WP

If low, add hydraulic oil (WP

okay, notify Unit Maintenance.