ENGINE

INSTALL ENGINE

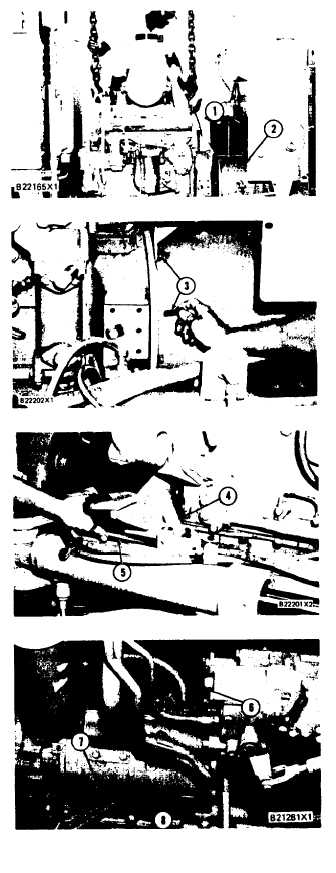

1. Inspect the O-ring seal on housing

make a replacement if necessary.

ENGINE

DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-2

(2) and

2. Fasten a hoist to the engine. Lift the engine and

put it in position in the machine.

NOTE: If necessary to make an alignment of the

flywheel and gear (1), remove the electric starting

motor and install a 5P7307 Engine Trunnion Tool

Group.

3. Move the engine back toward the transmission

until the flywheel and gear are in alignment.

4. Install bolts (3) to fasten the adapter to the

flywheel housing.

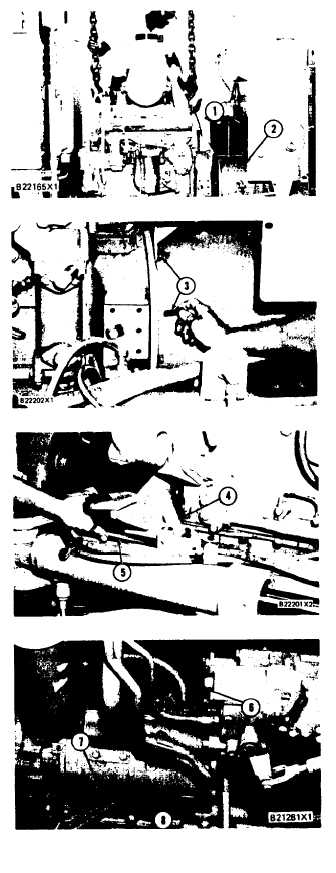

5. Install theoriginal amount of shims (5) in their

correct locations under the engine front sup-

port (4). Install the front support bolts.

Tighten bolts to a torque of 150 ± 20 lb.ft.

(205 ± 27 N•m).

6. If the electric starting motor was removed, in-

stall motor (8) and install wiring harness (7)

and cables (6) in position on the motor.

1-185