TM 5-3805-261-34

TRANSMISSION MAINTENANCE.

14-2.

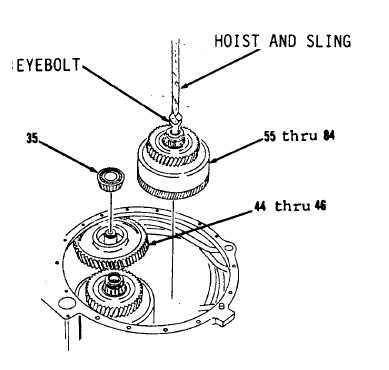

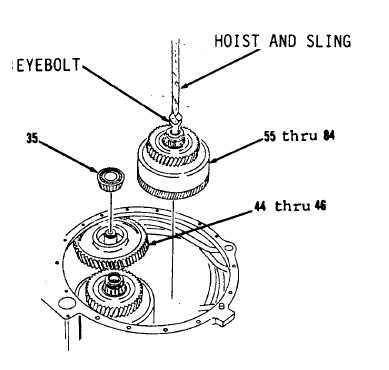

Transmission Assembly. (Sheet 7 of 20)

DISASSEMBLY

34. Lift up and push down on items 44

thru 46 as an assembly to free

roller bearing (35, Figure 14-9).

35. Remove roller bearing (35).

NOTE

The following is a mainte-

nance procedure for the

removal of the forward

directional clutch. The

maintenance procedure for the

reverse directional clutch is

identical.

36. Install 3/4-10NC forged eyebolt

in items 55 thru 84 as an

assembly.

WARNING

Weight of each directional

clutch is approximately 80

lbs. Use adequate hoist and

sling for lifting. Failure

to follow this procedure may

cause INJURY. If you are

injured, seek medical aid

immediately.

37. Attach hoist and sling to

3/4-10NC forged eyebolt.

38. Lift up on items 44 thru 46 as an

assembly to allow removal of

items 55 thru 84 as an assembly.

39. Remove items 55 thru 84 as an

assembly and place on workbench

to be disassembled later.

40. Remove hoist and sling.

41. Remove 3/4-10NC forged eyebolt.

Go to Sheet 8

14-9

Figure 14-9.