TM 5-380-261-34

ENGINE MAINTENANCE. (cont)

13-8.

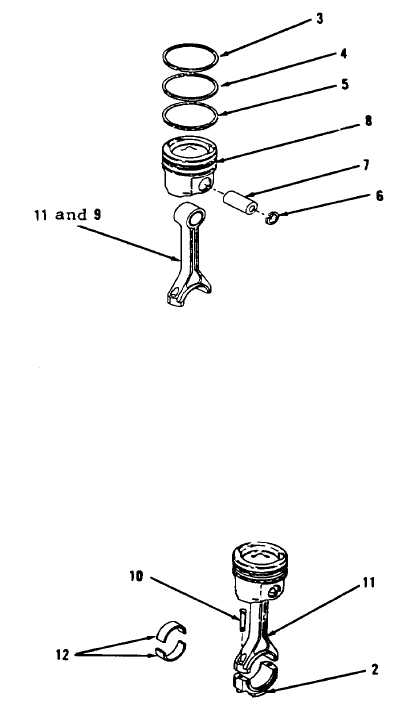

Piston and Connecting Rod. (Sheet 11 of 12)

INSTALLATION (cont)

4.

Install pin (7) and two retaining

rings (6) in piston (8).

CAUTION

Piston ring expander must be

used to install rings. Use

of any other tool may result

in damage to piston lands.

5.

Install oil ring (5) over spring

in lowest groove with ring gage

180 degrees from spring joint.

6.

Using ring expander, install

piston rings (4 and 3). Stagger

ring gaps 120 degrees, making

sure the letters UP is toward top

of piston rings (4 and 3).

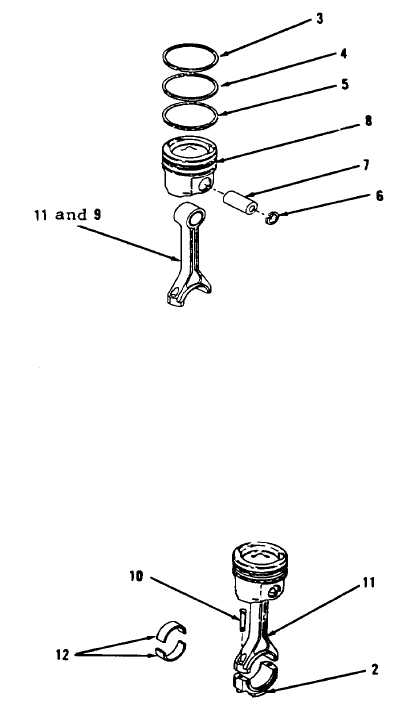

7.

Install two bearings (12) into

cap (2) and connecting rod (11,

Figure 13-48).

8.

Install bolts (10) into

connecting rod (11).

9.

Repeat steps 1 thru 4 for remain-

ing pistons and connecting rod

assemblies.

10. Rotate crankshaft counterclock-

wise on front of cylinder block

until bearing journal for piston

to be installed is bottom, dead

center.

11. Using clean oil, swab cylinder

lines and bearing journal on

cylinder block.

12. Using clean oil, dip piston (8).

13. Inspect piston rings, making sure

that gaps are 120 degrees apart.

Go to Sheet 12

13-50

Figure 13-47.

Figure 13-48.