TM 5-3805-261-34

ENGINE MAINTENANCE. (cont)

13-8.

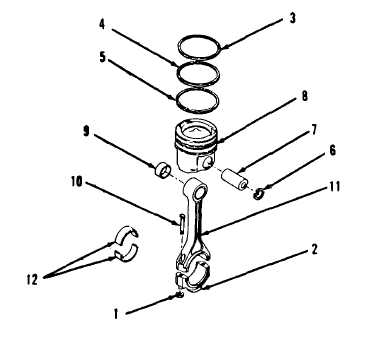

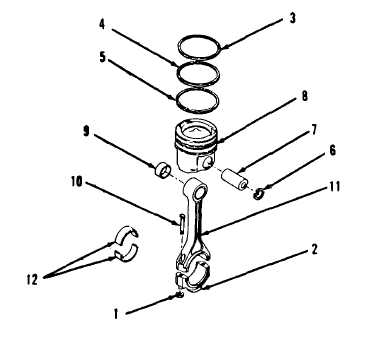

Piston and Connecting Rod. (Sheet 6 of 12)

REMOVAL (cont)

NOTE

Perform the following step

only if piston pin bearing

needs replacement.

13. Using press and rod to press out

bearing, remove bearing (9), if

necessary.

CLEANING

Clean all parts. Refer to Chapter 2.

INSPECTION

NOTE

Sets of bearings, connecting

rods and caps must be

installed in the same

cylinder from which they were

removed. Keep each set

separate. Inspect one at a

time.

1.

Inspect cap (2) and connecting

rod (11, Figure 13-44). Replace

as an assembly if cracked,

pitted, scored or excessively

worn.

2.

Inspect piston (8). Replace if

cracked, scored, grooves damaged

or signs of overheating.

3.

Measure bore diameter of piston

pin bearing (9). Use bore gage

and measure in two places, 90

degrees apart. The correct

dimension is 1.7012 inches.

Replace piston pin bearing (9) if

dimension is not correct.

4.

Measure bore diameter in piston

(8) for pin (7). Use bore gage

and measure in two places, 90

degrees apart. The correct

dimension is 1.07006 inches.

Replace piston (8) if dimension

is not correct.

Go to Sheet 7

13-45

Figure 13-44.