TM 5-3805-261-34

ENGINE MAINTENANCE. (cont)

13-8.

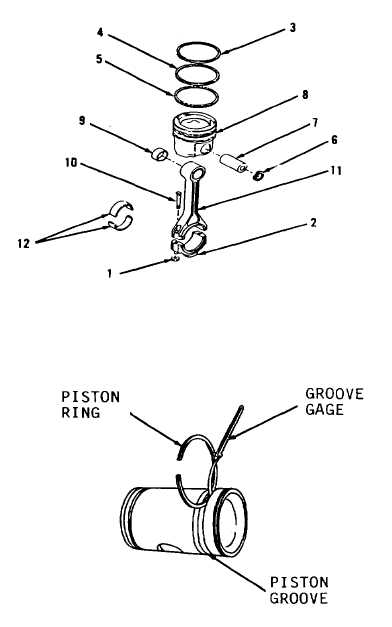

Piston and Connecting Rod. (Sheet 7 of 12)

INSPECTION (cont)

5.

Using feeler gage, measure

clearance between pin (7) and

bearing (9). Clearance between

new parts should be .0003 to

.0013 inch. Maximum clearance

permissible for worn parts should

not exceed .002 inch.

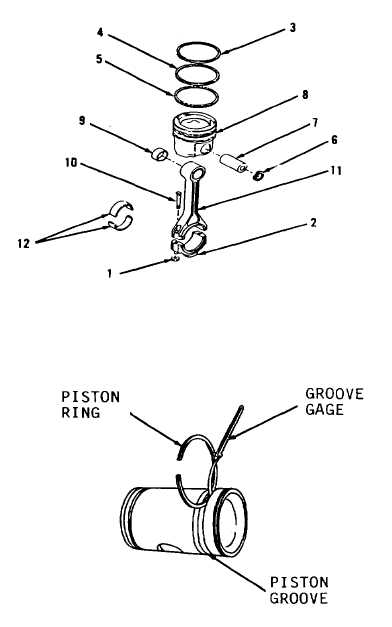

6.

Inspect top ring and second ring

piston grooves for burrs and

wear. Oil holes should be open.

7.

Using piston ring groove gage

(Figure 13-45), measure side

clearances. Put pin end of

number 2 gage in ring groove at

four places around the piston.

Check both grooves. Piston is

reusable if there is clearance

between flat edge of gage and

piston. Both grooves must be

good to reuse piston. Replace

piston if flat edge of groove

gage is in contact with piston at

any test point.

8.

Using a micrometer, measure

outside diameter of pin (7,

Figure 13-44). Correct dimension

is 1.6998 inches. Replace if

reading is not correct.

9.

Inspect retaining rings (6).

Replace if damaged or if

resiliency is lost.

10. Remove and inspect nuts (1) and

bolts (10). Replace if cracked,

broken, distorted or threads

damaged.

Go to Sheet 8

13-46

Figure 13-44.

Figure 13-45.