TM 5-3805-261-34

ENGINE MAINTENANCE.

13-8.

Piston and Connecting Rod. (Sheet 10 of 12)

INSTALLATION

NOTE

Connecting rod must be heated

for installation of bearing.

Do not use a torch.

1.

Heat connecting rod (11, Figure

13-46) in oven to 300 to 350

degrees F.

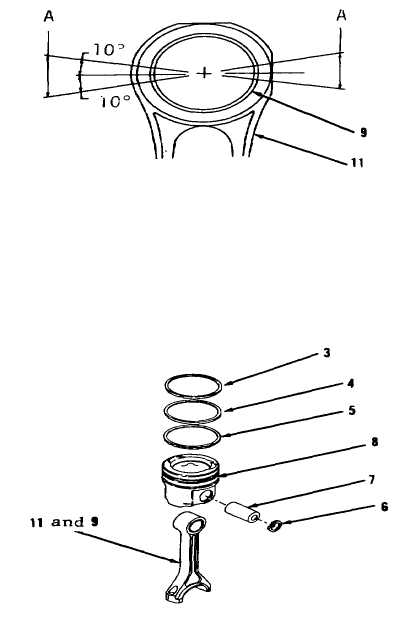

NOTE

Junction of piston pin

bearing must be assembled

within either area "A" (90

degrees + 10 degrees from

centerline through connecting

rod bore) as shown. Install

bearing so that oil hole in

bearing alines with oil hole

in connecting rod.

2.

Using rod and press, install new

bearing (9), if removed. Aline

oil holes. Using boring machine,

bore to 1.7012 inches.

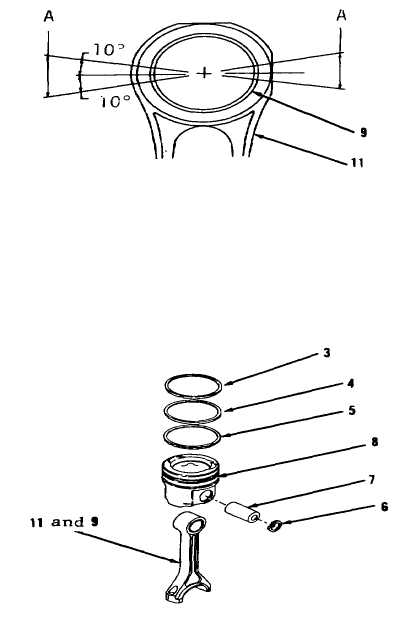

NOTE

Check piston and connecting

rod sets before assembly to

ensure that parts are matched

correctly.

3.

Install items 11 and 9 as an

assembly into piston (8, Figure

13-47) with bearing tab groove on

same side as valve cutouts in

piston head.

Go to Sheet 11

13-49

Figure 13-46.

Figure 13-47.