TM 5-3805-261-34

ENGINE MAINTENANCE. (cont)

13-5.

Crankshaft Main Bearings. (Sheet 12 of 12)

INSTALLATION (Intermediate Main

Bearings)

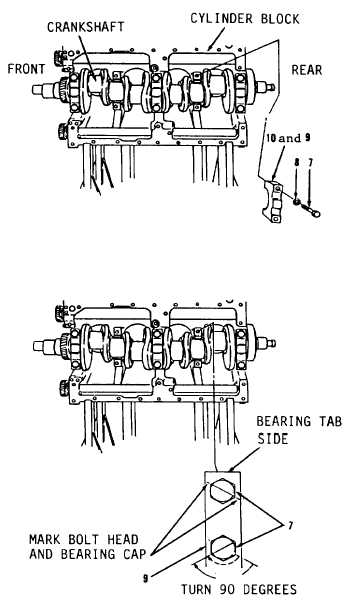

1.

Position two items 10 and 9 as an

assembly (Figure 13-24) under

crankshaft journal of inter-

mediate main bearing, alining

holes.

2.

Coat four washers (8) and bolts

(7) with clean engine oil and

install finger tight.

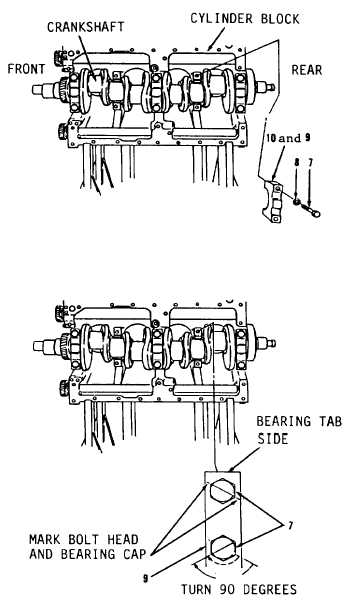

3.

Tighten two of four bolts (7) at

bearing tab side of two bearing

caps (9, Figure 13-31) to 30

ft-lb torque.

4.

Tighten two of four bolts (7)

opposite bearing tab side of two

intermediate bearing caps (9) to

30 ft-lb torque.

5.

Mark four bolts (7) and two

bearing caps (9) with chalk.

6.

Tighten two of four bolts (7)

opposite bearing tab side of two

intermediate main bearing caps

(9) a further 90 degrees, using

chalk mark as an aid in

estimating how far to tighten two

of four bolts (7).

7.

Tighten two of four bolts (7) at

bearing tab side of two inter-

mediate main bearing caps (9) a

further 90 degrees.

NOTE

Return 130G Grader to

original equipment condition.

End of Task

13-32

Figure 13-

Figure 13-