TM 5-3805-261-34

ENGINE MAINTENANCE.

13-5.

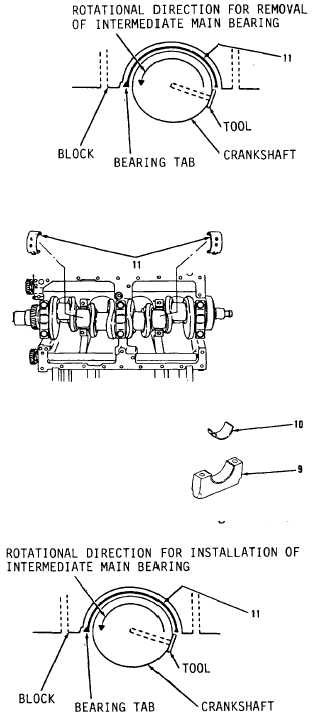

Crankshaft Main Bearings. (Sheet 9 of 12)

REMOVAL (Intermediate Main Bearings)

3.

Install tool in oil hole of

crankshaft journal where two

bearings (11, Figure 13-26) are

to be removed.

CAUTION

Crankshaft must be rotated in

direction of normal engine

rotation when removing main

bearings. Engine rotation is

counterclockwise when viewed

from rear. Failure to follow

this procedure could result

in damage to block, crank-

shaft, or both.

4.

Rotate crankshaft and tool

against upper half of two

intermediate main bearings (11)

in direction of normal engine

rotation.

5.

Remove and discard upper half of

two intermediate main bearings

(11, Figure 13-27).

CLEANING

Clean all parts. Refer to Chapter 2.

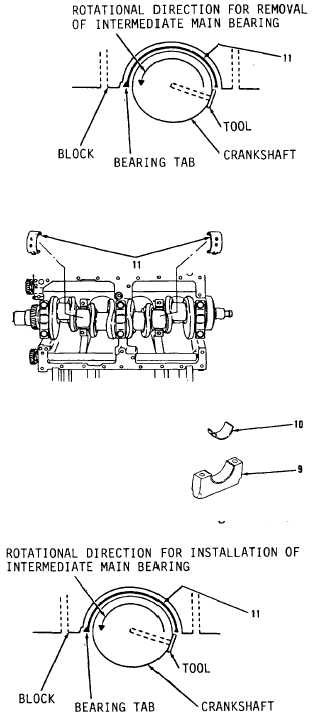

INSPECTION (Intermediate Main Bearings)

1.

Coat two new lower intermediate

main bearings (10, Figure 13-28)

with clean engine oil.

2.

Install in two crankshaft bearing

caps (9) with bearing tab toward

tab locator in block.

3.

Install tool in crankshaft

journal (Figure 13-29).

Figure 13-29.

Figure 13-28.

Figure 13-27.

Figure 13-26.

Go to Sheet 10

13-29