TM 5-3805-261-34

ENGINE MAINTENANCE. (cont)

13-5.

Crankshaft Main Bearings. (Sheet 10 of 12)

INSPECTION (Intermediate Main Bearings)

(cont)

CAUTION

When installing intermediate

bearings in cylinder block,

crankshaft must be rotated in

OPPOSITE DIRECTION from

normal engine rotation.

Failure to follow this procedure

could result in damage to block,

crankshaft, or both.

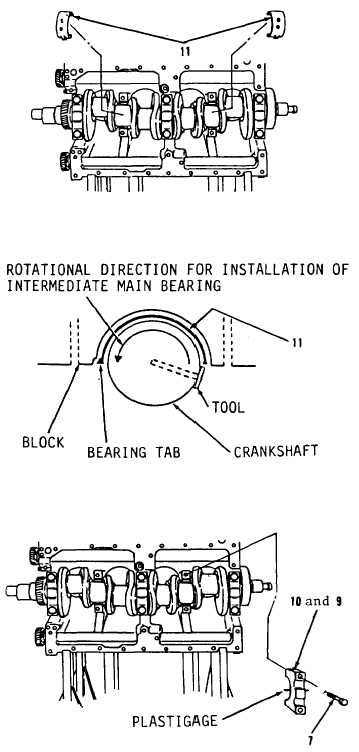

4.

Position two new upper inter-

mediate main bearings (11, Figure

13-27) in cylinder block above

crankshaft journal with bearing

tab toward tab locator in block.

5.

Rotate crankshaft and tool

against two new upper inter-

mediate bearings (11) to push

bearings (11, Figure 13-29) into

position. For this step, rotate

crankshaft clockwise when engine

is viewed from rear.

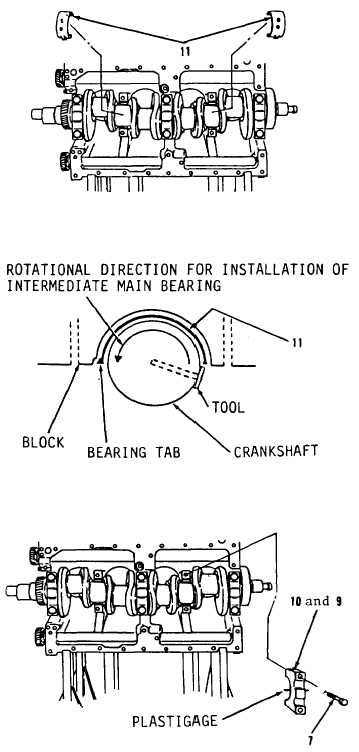

6.

Cut two pieces of plastigage

approximately 1-1/2 inches long

and position one piece on inside

surface of bearing (10) in each

of two crankshaft bearing caps

(9, Figure 13-30).

CAUTION

Arrow on bottom of bearing

caps must face front of

engine; number on cap must

match bearing number on

outside of cylinder block.

Failure to follow this proce-

dure could result in damage

to equipment.

7.

Position two items 10 and 9 as an

assembly and plastigage under

crankshaft journal, alining holes.

8.

Coat four bolts (7) with clean

engine oil and install finger

tight.

Figure 13-30.

Figure 13-

Figure 13-

Go to Sheet 11

13-30