TM 5-3805-261-34

ENGINE MAINTENANCE. (cont)

13-5.

Crankshaft Main Bearings. (Sheet 6 of 12)

INSPECTION (Front, Center and Rear Main

Bearings) (cont)

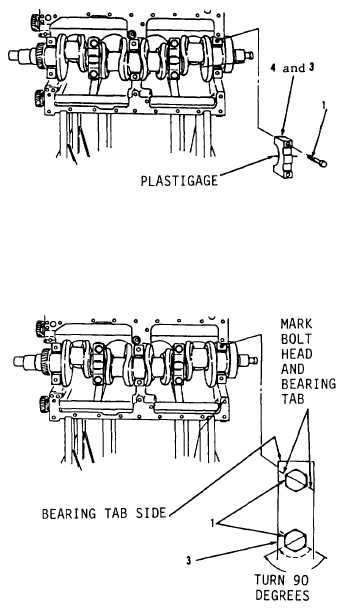

8.

Position one piece of plastigage

inside surface of lower main

bearing (4) in each crankshaft

bearing cap (3, Figure 13-22).

CAUTION

Arrow in bottom of crankshaft

bearing cap must face front

of engine; number on cap must

match bearing number on

outside of cylinder block.

Failure to follow this

procedure could result in

damage to equipment.

9.

Position three items 4 and 3 as

an assembly and plastigage under

crankshaft journal, alining

holes.

10.

Coat six bolts (1) with clean

engine oil and install finger

tight.

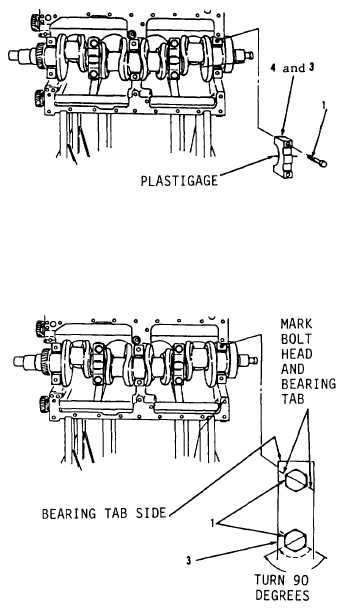

11.

Tighten six bolts (1) at bearing

tab side of bearing cap (3,

Figure 13-23) to 30 ft-lb torque.

12.

Mark six bolts (1) and three

bearing caps (3) with chalk.

13.

Tighten three of six bolts (1)

opposite tab side of three

bearing caps (3) a further 90

degrees, using chalk mark as an

aid in estimating how far to

tighten three of six bolts (1).

Go to Sheet

7

13-26

Figure 13-22.

Figure 13-23.