TM 5-3805-261-34

STARTING SYSTEM MAINTENANCE. (cont)

4-12.

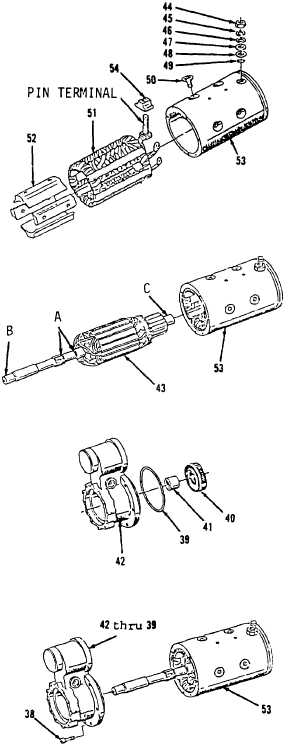

Starting Motor (Bosch). (Sheet 8 of 11)

ASSEMBLY (cont)

5.

Install new seal (49), insulator

(48), washers (47 and 46), lock-

washers (45) and nut (44) on

field coil (51, Figure 4-80) pin

terminal. Tighten nut (44) to 18

ft-lb torque. Remove pole

spreader.

Do not allow grease or oil to

get on commutator or arma-

ture.

6.

Using clean grease, lightly

lubricate points (A), (B) and (C)

of armature (43, Figure 4-79)

shaft. Apply clean lubricating

oil to remaining areas of

armature (43) shaft.

7.

Install armature (43) in housing

(53).

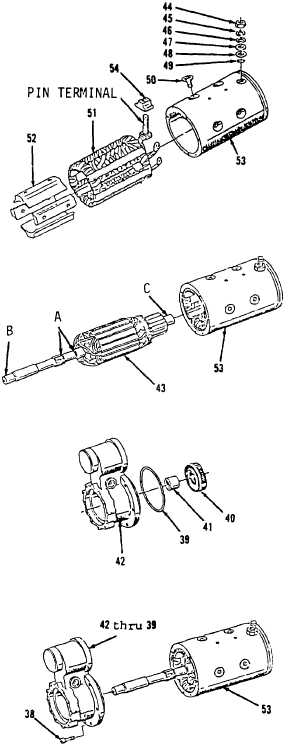

8.

Using suitable driver and press,

install new bearing (41) in

housing (42, Figure 4-78).

9.

Using clean grease, lubricate

outer diameter of new seal (40).

10.

Install new preformed packing

(39) in groove of housing (42).

11.

Using clean oil, lubricate outer

diameter of new preformed packing

(39).

12.

Position items 42 thru 39 as an

assembly on housing (53, Figure

4-77) alining matchmarks.

13.

Install six screws (38) and

tighten to 9 ft-lb torque.

Go to Sheet 9

4-72

CAUTION

Figure 4-80.

Figure 4-79.

Figure 4-78.

Figure 4-77.