TM 5-3805-261-20

WIRING HARNESS MAINTENANCE.

7-117.

General Repair. (Sheet 8 of 15)

(6)

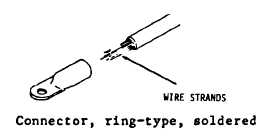

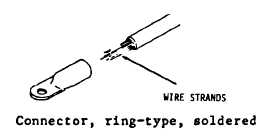

Ring-type connector, soldered.

DISASSEMBLY

Remove and discard defective terminal (Figure

7-196). Cut wire close to terminal.

ASSEMBLY

NOTE

New terminal must be selected to

match the ring size of the terminal

with the mounting screw at the

terminal connection. New terminal

must also match the wire solder area

with the size of the wire.

1.

Strip wire, refer to chart. Do not cut or nick

wire strands (Figure 7-191).

2.

Tin bare wires (Figure 7-196). Use resin-

core solder to coat bare wires. If using

solid core solder, clean wires with flux

before tinning.

3.

Insert in new terminal.

4.

Secure

terminal

and

wire

to

prevent

movement.

5.

Solder terminal and wires. Fill terminal

cavity with melted solder. Allow to cool

several minutes before moving wire or

terminal.

Figure 7-196

Go to Sheet 9

7-299