TM 5-3805-293-23-2

0026

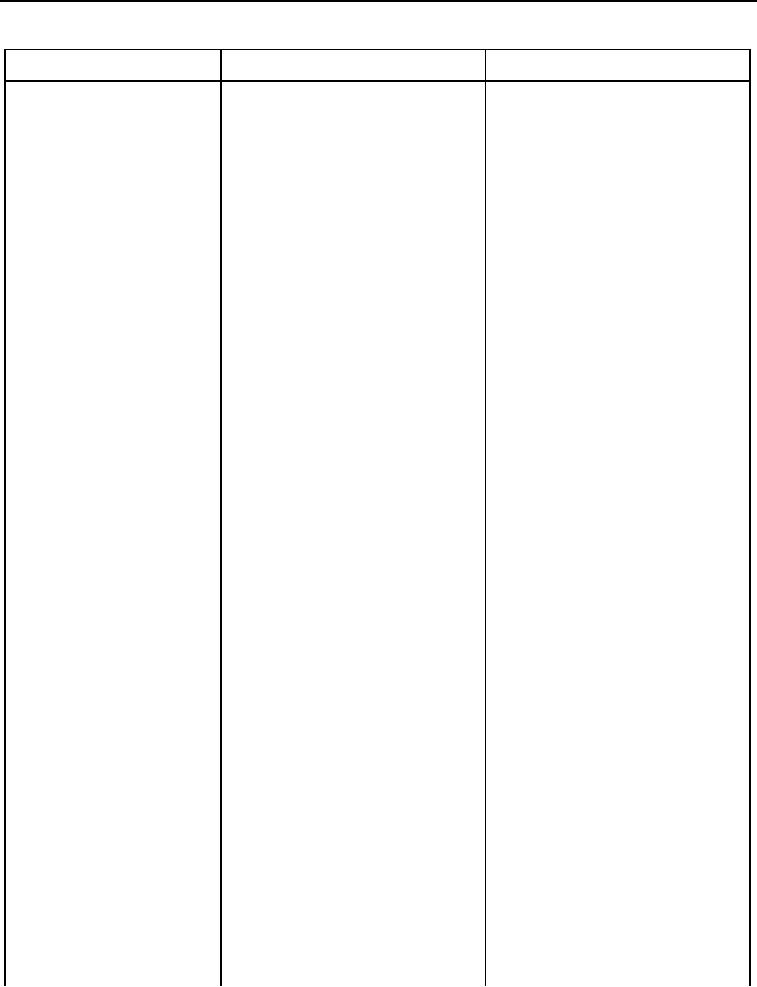

Table 1. Implement Code (0041-03 to 0600-04) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0600-04 Main Hydraulic

5. Using the MSD (WP 0006), select 0600-04 Code Active - Repeat

Pump Discharge Pressure

Implement 120M and verify 0600- troubleshooting code from the

Sensor Voltage Below

04 is not active.

beginning.

Normal - Continued

0600-04 Code Not Active -

Troubleshooting complete.

Test Step 3. Test for Shorted Cab

Lower Wiring Harness.

1. Turn ignition switch and battery

disconnect switch to the OFF

position.

2. Disconnect the cab lower wiring

harness connector P-C41 (WP

0009, Figure 68) from implement

ECM J1 (WP 0009, Figure 69)

(WP 0268).

3. Using digital multimeter, measure

Continuity - Proceed to Test Step 4.

for resistance between cab lower

No Continuity - Replace the

wiring harness connector P-C41

implement 1 ECM (WP 0268).

(WP 0009, Figure 68) terminal 22

Connect the rear chassis wiring

and terminal 13.

harness connector FA-C6 (WP 0009,

There should be no continuity.

Figure 212) to hydraulic oil

temperature sensor (WP 0059).

Proceed to step 4.

4. Using the MSD (WP 0006), select 0600-04 Code Active - Repeat

Implement 120M and verify 0600- troubleshooting code from the

04 is not active.

beginning.

0600-04 Code Not Active -

Troubleshooting complete.

Test Step 4. Test for Shorted Rear

Chassis Wiring Harness.

1. Disconnect the rear chassis wir-

ing harness connector FA-C23

(WP 0009, Figure 17) from cab

lower wiring harness connector P-

C71 (WP 0009, Figure 18) (WP

0188).

2. Disconnect the rear chassis wir-

ing harness connector FA-C22

(WP 0009, Figure 47) from cab

lower wiring harness connector P-

C69 (WP 0009, Figure 46) (WP

0188).

0026-93