TM 5-3805-293-23-2

0026

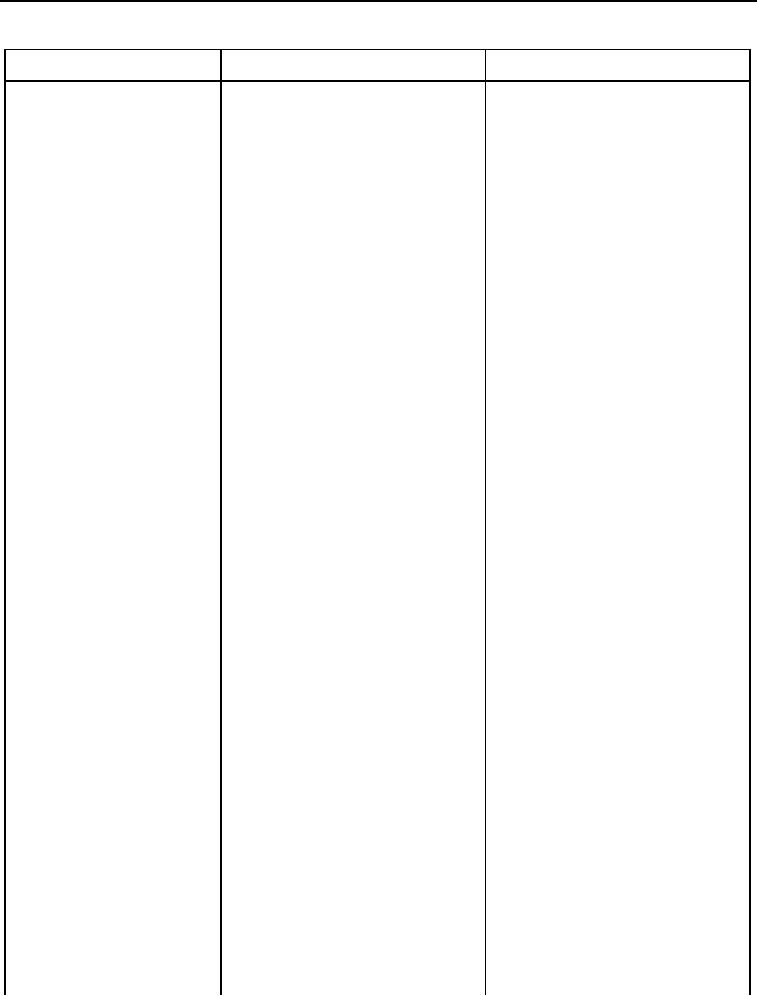

Table 1. Implement Code (0041-03 to 0600-04) Troubleshooting Procedures - Continued.

CDI FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0600-03 Main Hydraulic

Test Step 5. Test for Shorted Cab

Pump Discharge Pressure

Lower Wiring Harness.

Sensor Voltage Above

1. Remove jumper wire between

Normal - Continued

rear chassis wiring harness con-

nector FA-C6 (WP 0009, Figure

212) terminal 1 and terminal 2.

2. Using digital multimeter, measure

Continuity - Proceed to Test Step 6.

for resistance between cab lower

No Continuity - Replace the

wiring harness connector P-C41

implement 1 ECM (WP 0268).

(WP 0009, Figure 68) terminal 22

Connect the rear chassis wiring

and all other P-C41 terminals

harness connector FA-C6 (WP 0009,

There should be no continuity.

Figure 212) to hydraulic oil

temperature sensor (WP 0059).

Proceed to step 3.

3. Using the MSD (WP 0006), select 0600-03 Code Active - Repeat

Implement 120M and verify 0600- troubleshooting code from the

03 is not active.

beginning.

0600-03 Code Not Active -

Troubleshooting complete.

Test Step 6. Test for Shorted Rear

Chassis Wiring Harness.

1. Disconnect the rear chassis wir-

ing harness connector FA-C23

(WP 0009, Figure 17) from cab

lower wiring harness connector P-

C71 (WP 0009, Figure 18) (WP

0188).

2. Using digital multimeter, measure

Continuity - Replace rear chassis

for resistance between rear chas-

wiring harness (WP 0188).

sis wiring harness connector FA-

Connect the cab lower wiring harness

C23 (WP 0009, Figure 17) termi-

connector P-C41 (WP 0009, Figure

nal 3 and all other FA-C23 termi-

68) to implement ECM J1 (WP 0009,

nals.

Figure 69) (WP 0268).

There should be no continuity.

Proceed to step 3.

No Continuity - Replace cab lower

wiring harness (WP 0266).

Connect the rear chassis wiring

harness connector FA-C6 (WP 0009,

Figure 212) to hydraulic oil

temperature sensor (WP 0059).

Proceed to step 3.

0026-91