ELECTRICAL SYSTEM

TM 5-3805-263-14&P-2

TESTING AND ADJUSTING

1. To adjust the pinion distance, connect the solen-

oid to a 12 volt battery as shown.

Momentarily flash the jumper lead from the mo-

tor terminal stud of the solenoid to the terminal stud

at (1) in the commutator end head to shift the solen-

oid and drive into the cranking position.

Remove the jumper lead.

NOTE: The drive will remain in the cranking posi-

tion until the battery is disconnected.

Push the drive toward the commutator end of the

motor to eliminate any slack movement in the link-

age and measure the distance between the outside

edge of the drive sleeve and the thrust washer. The

distance (3) must he .02 to .05 in. (0.51 to 1.27 mm).

Adjust to this dimension by turning the adjusting

nut (2) in or out as required.

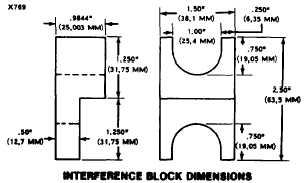

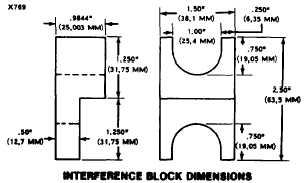

2. To test assembly of solenoid, it will be necessary

to have an interference block cut to the dimen-

sions shown.

Connect the solenoid to 24 volts as shown.

Position the .9844 in. (25.003 mm) side of the

interference block against the pinion as shown and

close the switch in the battery circuit,

With the switch closed and the .9844 in. (25.003

mm) side of the interference block in place, the test

light must not light. Make sure the interference

block is against the drive gear and not against the

drive sleeve.

CAUTION

Due to the amount of current being passed

through the solenoid series winding, these

tests should be made as brief as possible.

If the test light lights, the solenoid has been assem-

bled wrong. Remove the cover from the solenoid and

check the contact component assembly. If the test

light does not light. connect a carbon pile between

the switch and battery and voltmeter to the terminals

(4) and (5).

1-78