ELECTRICAL SYSTEM

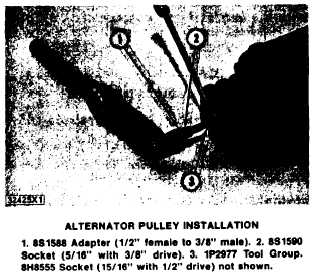

Delco-Remy Alternator; Pulley Nut Tightening

Tighten nut holding the pulley to a torque of 75 ±

5 lb. ft. (100 ± 7 N•m) with the tools shown.

STARTING SYSTEM

Tools Needed: 5P300 Electrical Tester

NOTE: Make reference to the instructions inside the

cover of the tester, when testing with the 5P300

Electrical Tester.

Use a D.C. Voltmeter to find the starting system

components which do not function.

Put the DISCONNECT SWITCH in the ON

position.

Move the starting control switch to activate the

starter solenoid. Starter solenoid operation can be

heard as the pinion of the starter motor is engaged

with the ring gear on the engine flywheel.

If the solenoid for the starter motor will not oper-

ate, it is possible that the current from the battery is

not getting to the solenoid. Fasten one lead of the

voltmeter to the connection (terminal) for the bat-

tery cable on the solenoid. Put the other lead to a

good ground. No voltmeter reading shows there is a

broken circuit from the

necessary when there is a

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

battery. More testing is

reading on the voltmeter.

The solenoid operation also closes the electric cir-

cuit to the motor. Connect one lead of the voltmeter

to the solenoid connection (terminal) that is fastened

to the motor. Put the other lead to a good ground.

Activate the starter solenoid and look at the volt-

meter. A reading of battery voltage shows the prob-

lem is in the motor. The motor must be removed for

further testing. No reading on the voltmeter shows

that the solenoid contacts do not close. This is an

indication of the need for repair to the solenoid or an

adjustment to be made to the starter pinion

clearance.

Make a test by fastening one voltmeter lead to the

connection (terminal) for the small wire at the solen-

oid and the other lead to the ground. Look at the

voltmeter and activate the starter solenoid. A volt-

meter reading shows that the problem is in the solen-

oid. No voltmeter reading shows that the problem is

in the heat-start switch or wiring.

Fasten one voltmeter lead to the heat-start switch

at the connection (terminal) for the wire from the

battery. Fasten the other lead to a good ground. No

voltmeter reading indicates a broken circuit from the

battery. Make a check of the circuit breaker and

wiring. If there is voltmeter reading, the malfunction

is in the heat-start switch or in the wiring.

Fasten one lead of the voltmeter to the battery wire

connection of the starter switch and put the other

lead to a good ground. A voltmeter reading indicates

a failure in the switch.

A starter motor that operates too slow can have an

overload because of too much friction in the engine

being started. Slow operation of the starter motor

can also be caused by shorts, loose connections

and/or dirt in the motor.

Pinion Clearance Adjustment (Prestolite)

There are two adjustments on this type motor.

Armature end play and pinion position.

Armature End Play

Adjust to .005 to .030 in. (0.13 to 0.76 mm) by

adding or removing thrust washers on the commuta-

tor end of the armature shaft.

Pinion Position

This adjustment is accomplished in two steps.

1-77