BASIC BLOCK

TM 5-3805-263-14&P-2

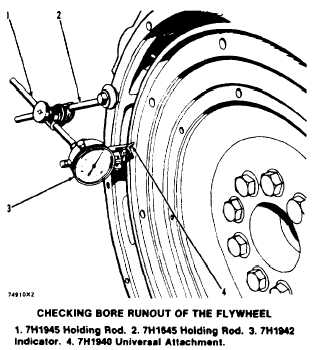

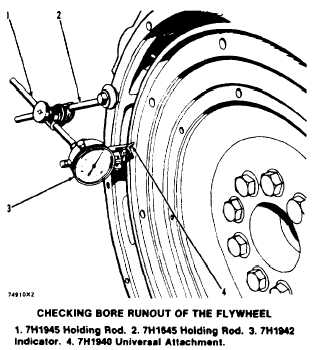

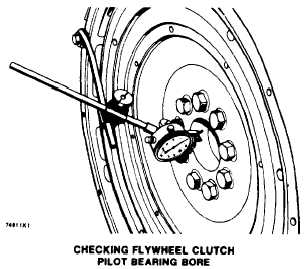

4. The difference between the lower and higher

measurements taken at all four points must not

be more than 0.15 mm (.006 in.), which is the

maximum permissible bore runout (radial ec-

centricity) of the flywheel.

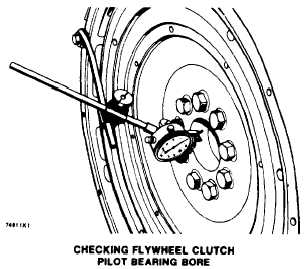

5. Runout (eccentricity) of the bore for the pilot

bearing for the flywheel clutch, must not exceed

0.13 mm (.005 in.).

1-74

TESTING AND ADJUSTING

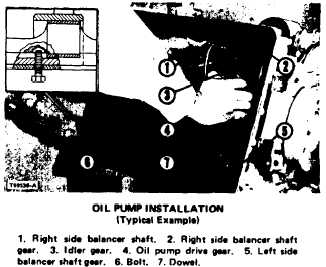

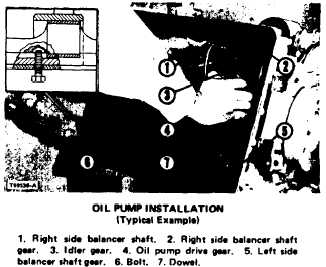

OIL PUMP INSTALLATION

The oil pump can be removed for inspection and

service without removing the timing gear cover.

With the cover in place, timing marks are not easy

to see. Therefore, time both balancer shafts, with

respect to No. 1 piston at TC or compression

stroke, in the following steps.

1.

2.

3.

4.

5.

6.

7.

Rotate the crankshaft to bring No. 1 piston to

TC on compression stroke.

Drive dowel (7) back so it is flush with

mounting face of oil pump mounting bracket.

Rotate both balancer shafts so the flat portion

is away from the oil pan plate. Install bolts (6)

so they enter in countersunk holes in balancer

shafts and limit shaft movement. The bolts

should not be tight against the shaft counter-

sunk hole bottom.

Position oil pump on bottom of engine block

and install the mounting bolts loosely.

Install shims if necessary, between pump

mounting pads and cylinder block to adjust

backlash to .002 to .006 in. (0.05 to 0.15 mm)

between gear (4) and (5) and between gears

(2) and (3).

Drive dowel (7) back in place, through mount-

ing bracket and into cylinder block. Tighten

the mounting bolts.

Remove bolts (6) and check to see that the

countersunk holes are aligned with holes in oil

pan plate when No. 1 cylinder is in TC

position.

Timing mark alignment information shown in

the SPECIFICATIONS is to be used when the

timing gear cover is removed.