BASIC BLOCK

TESTING AND ADJUSTING

TM 5-3805-263-14&P-2

3.

4.

5.

6.

7.

8.

9.

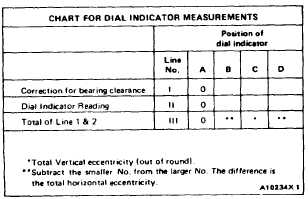

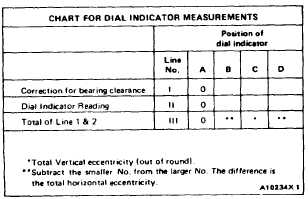

Turn the crankshaft to put the dial indicator at

(A). Adjust the dial indicator to “0” (zero).

Turn the crankshaft counterclockwise to put the

dial indicator at (B). Write the measurement in

the chart.

Turn the crankshaft counterclockwise to put the

dial indicator at (C). Write the measurement in

the chart.

Turn the crankshaft counterclockwise to put the

dial indicator at (D). Write the measurement in

the chart.

Add lines I & II by columns.

Subtract the smaller number from the larger

number in line Ill in columns (B) & (D). The

result is the horizontal “eccentricity” (out of

round). Line Ill, column (C) is the vertical

eccentricity.

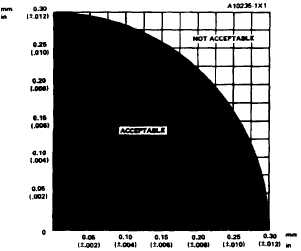

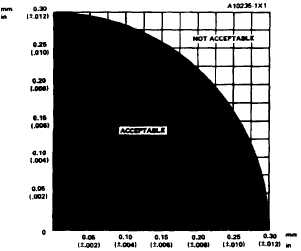

On the graph for total eccentricity find the point

of intersection of the lines for vertical eccentri-

city and horizontal eccentricity.

10. If the point of intersection is in the range marked

“Acceptable” the bore is in alignment. If the

point of intersection is in the range marked “Not

Acceptable”

the flywheel housing must be

changed.

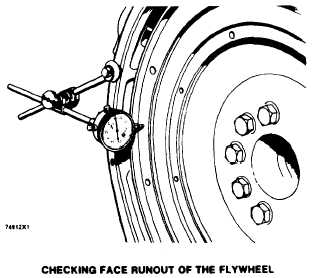

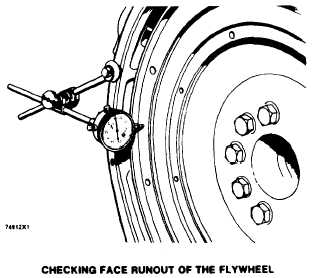

Face Runout (axial eccentricity)

of the Flywheel

1. Install the dial indicator as shown. Put a force on

the crankshaft the same way before the indicator

is read to be sure the crankshaft end clearance

(movement) is always removed.

2. Set the dial indicator to read 0.0 mm (.000 in.).

3. Turn the flywheel and read the indicator every

90°.

4. The difference between the lower and higher

measurements taken at all four points must not

be more than 0.15 mm (.006 in.), which is the

maximum permissible face runout (axial eccen-

tricity) of the flywheel.

Bore Runout (radial eccentricity)

of the Flywheel

1. Install the dial indicator (3) and make an adjust-

ment of the universal attachment (4) so it makes

contact as shown.

2. Set the dial indicator to read 0.0 mm (.000 in.).

3. Turn the flywheel and read the indicator every

90°.

1-73