BASIC BLOCK

TESTING AND ADJUSTING

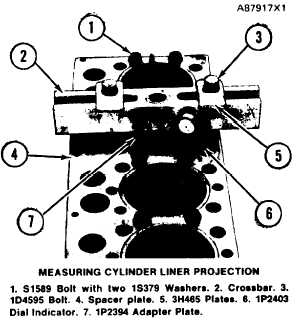

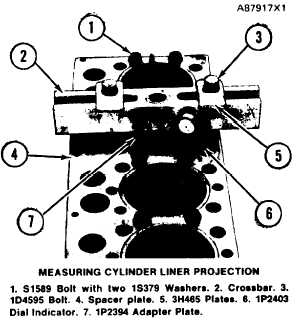

4. Install the 1P5512 Contact Point on dial indica-

tor (6). Put the dial indicator in the 1P2402

Gauge Body. To adjust the dial indicator to zero,

put dial indicator and gauge body on the 1P5507

Gauge. Move the dial indicator until the hand

moves 1/4 turn. Tighten bolt on body to hold the

dial indicator in this position. Turn the dial face

until the zero is in alignment with the hand.

5. Measure the cylinder liner projection as close as

possible to the four corners of the adapter plate

on the liner. The liner projection must be 0.033

to 0.175 mm (.0012 to .0069 in.). The difference

between the four measurements must not be

more than 0.05 mm (.002 in.). The difference in

the average cylinder liner projection of liners

next to each other must not be more than 0.05

mm (.002 in.). The maximum difference in the

average projection for all cylinder liners must

not be more than 0.10 mm (.004 in.).

NOTE: If the liner projection changes from point to

point around the liner, turn the liner to a new position

in the bore. If the liner projection is still not to

specifications, move the liner to a different bore.

installed in the correct position.

Cylinder liner projection can be adjusted by the

removal of material from (machining) the contact

face of the cylinder block with the use of 8S3140

Cylinder Block Counterboring Tool Arrangement.

6. When the cylinder liner projection is correct, put

a temporary mark on the liner and the spacer

plate so at final installation the liner can be

TM 5-3805-263-14&P-2

ADJUSTMENT SHIMS FOR LINER PROJECTION

SHIM THICKNESS, COLOR CODE, AND PART NUMBER

0.18 mm

0.20 mm

0.23 mm

0.38 mm

0.76 mm

(.007 in.) (.008 in.) (.009 in.) (.015 in.)

(.030 in.)

BLACK

RED

GREEN

BROWN

BLUE

8S6045

8S6046

8S6047

8S6048

8S6049

CYLINDER BLOCK

The bore in the block for main bearings can be

checked with the main bearing caps installed

without bearings. Tighten the nuts holding the caps

to the torque shown in the SPECIFICATIONS.

Alignment error in the bores must not be more

than 0.08 mm (.003 in.). 1P3537 Dial Bore Gauge

Group can be used to check the size of the bores.

FLYWHEEL AND FLYWHEEL HOUSING

Installing Ring Gear

Heat the ring gear to install it. Do not heat to more

than 315°C (600°F). Install the ring gear so the

chamfer on the gear teeth are next to the starter

pinion when the flywheel is installed.

Face Runout (axial eccentricity)

of the Flywheel Housing

Tools Needed:

8S2328 Dial Indicator Group.

If any method other than given here is used, al-

ways remember bearing clearances must be removed

to get correct measurements.

1-71