POWER TRAIN

DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-2

BRAKE AND WHEEL SPINDLE HOUSINGS

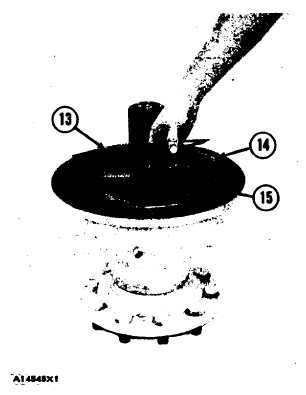

14. Install hub (15) on the wheel spindle.

15. Put clean SAE 30 oil on the discs and on

the disc assemblies.

16. Put discs (13) and disc assemblies (14) in

position in the wheel spindle housing start-

ing with a disc. There are ten discs and nine

disc assemblies. Make sure there is a disc

assembly between each disc.

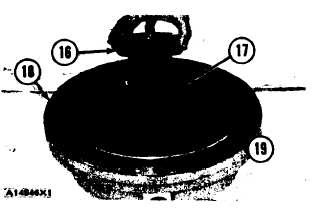

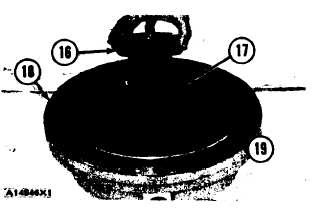

17. Install the O-ring seal in cover (18).

18. Install O-ring seal ( 19) on cover (18). Put

clean grease on the two O-ring seals.

19. Lower the temperature of bearing cup (17)

and install it in cover (18).

20. Install two 5/8”-11 NC forged eyebolts in

cover (18). Fasten a hoist to the eyebolts.

21. Put cover (18) in position on wheel spindle

housing (3). Remove the hoist and the

eyebolts.

22. Install the bolts and the plate that hold

cover (18) to the housing.

23. Install bearing cone (16) on the wheel

spindle and in cover (18).

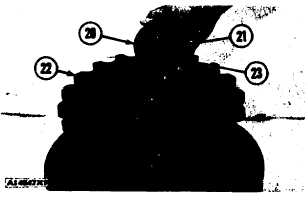

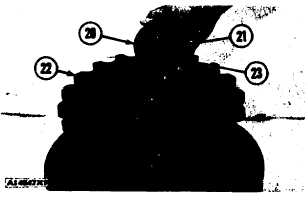

24. Put sprocket (22) in position on the splines

of the wheel spindle.

NOTE: The sprocket for the front brake and wheel

spindle housing must be installed with the teeth

next to the cover. The sprocket for the rear brake

and wheel spindle housing must be installed with

the teeth away from the cover.

25. Put retainer (20) in position on the wheel

spindle without shims. Install bolts (23).

Tighten the bolts to a torque of 35 lb. ft. (4.8

mkg) while turning the housing. Remove the

bolts and the retainer. Measure the distance

between the end of the sprocket and the wheel

spindle. Install the retainer and shims (21)

that are the same thickness as the distance

measured minus .010 to .015 in. (0.25 to 0.38

mm). Install bolts (23) and tighten to 192 ±

10 lb. ft. (260 ± 14 N.m). Install the wire on

the bolts.

end by:

a) install brake and wheel spindle housings

2-52