POWER TRAIN

DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-2

BRAKE AND WHEEL SPINDLE HOUSINGS

ASSEMBLE BRAKE AND WHEEL SPINDLE

HOUSINGS

Tools Needed

A B

Seal Installer

1

Adapter

1

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

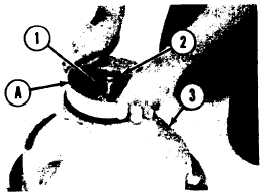

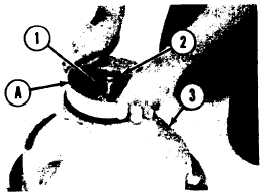

Lower the temperature of bearing cup (1)

and install it in housing (3).

Make sure the Duo-Cone seals for the wheel

spindle housing (3) and the wheel spindle

are clean and dry. Make sure all metal

surfaces that the seals make contact with

are clean and dry. Install Duo-Cone seal (2)

in wheel spindle housing (3) with tool (A).

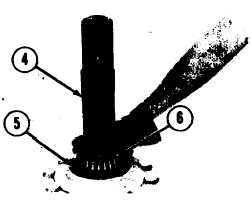

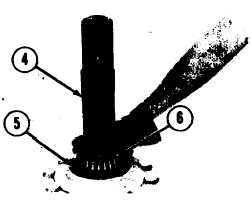

Install Duo-Cone seal (5) on wheel spindle

(4) with tool (A). Put a small amount of oil

on the metal surfaces of the seals that make

contact with each other.

Heat bearing cone (6) in oil to a maximum

temperature of 275oF (135oC). Install

bearing cone (6) on the shaft of wheel

spindle (4).

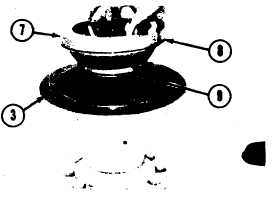

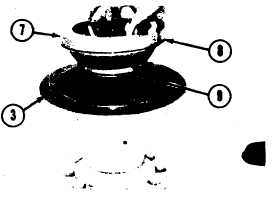

Install two 5/8”-11 NC forged eyebolts in

housing (3). Fasten a hoist to the eyebolts.

Put housing (3) in position on wheel spindle

(4). Be careful not to damage the Duo-Cone

seals. Remove the hoist and the eyebolts.

Install small O-ring seal (9) on the piston.

Install the large O-ring seal (8) on piston

(7). Install piston (7) in housing (3).

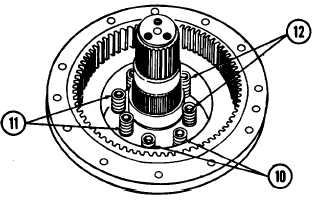

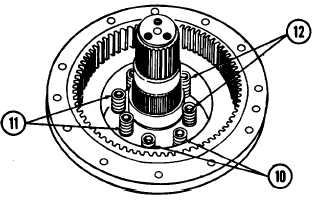

Put springs (11) in position in spindle hous-

ing.

Put washers (10) in position on springs (11).

Put bolts (12) in place, through the washers

(10) and springs (11).

Tighten bolts (12) until pressure is felt from

springs (11).

Tighten bolts (12) to 30 ± 5 lb. ft. (40 ± 7

N.m).

Oil the springs (11) with clean SAE 30 oil.

2-51