POWER TRAIN

DISASSEMBLY AND ASSEMBLY

8.

9.

10.

11.

12.

FINAL DRIVES

TM 5-3805-263-14&P-2

Remove O-ring seal (3) from the housing.

Remove bearing (4) from the shaft.

Remove bolts (5) that hold retainer (6) to the

housing. Remove retainer (6). Also, remove

the shim pack under retainer.

Remove the washer that is between the final

drive housing and retainer (6). The washer is

in three sections.

Install two 5/8”-11 NC forged eyebolts (11)

and nuts in the housing as shown. Put a fork

lift truck in position under the housing.

Install tooling (F) on the lift truck and the

eyebolts.

Pull the outer housing (8) from the inner

housing with tooling (F).

CAUTION: Use care when removing outer hous-

ing so that seal (12) in outer housing is not damag-

ed.

13.

14.

15.

16.

17.

18.

19.

Remove two oscillation bearing rings (9)

from the housings. Remove washer (7) from

the inner housing. Washer (7) is in three

sections.

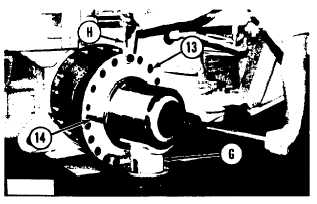

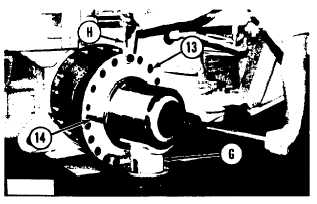

Put tooling (G) and a floor jack in position

under inner housing (13). A rag can be put

between tooling (G) and the housing to

prevent damage to the housing.

Remove nuts (10) and the washers that hold

inner housing (13) to the bevel gear case.

Install two 3/4”-10 NC forcing screws (14)

in the housing. Remove the inner housing

far enough to install tooling (H) on the

housing. Fasten a hoist to tooling (H). Rut

an axle in position in the final drive housing

to help keep the housing in balance.

Install a wire around the forcing screws and

the planet carrier to keep the planet carrier

from falling. Remove inner housing (13) and

the planet carrier. Weight is 360 lb. (163 kg).

Remove the O-ring seal from the inside surface

of inner housing (13). Remove seal (12) only if

it is leaking oil.

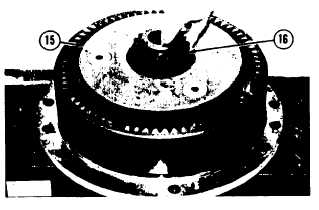

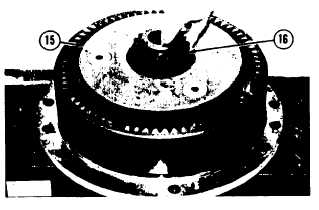

Rut the final drive housing in position on

blocks with the planet carrier up. Remove

the wire and the forcing screws from the

housing.

Remove pinion (16) from planet carrier

(15). Fasten a hoist to planet carrier (15)

and remove it. Weight is 90 lb. (41 kg).

2-57