TM 5-3805-263-14&P-1

The Type II machine is equipped with all special tools

and equipment needed for sectionalization. Stored in the

tool box is a cable extraction tool 5R7047, and various

equipment such as jacks, articulation links, jumper

hoses and cables, tiedown straps, drive shaft guard, etc.

A remote control box is stored on the frame just forward

of the operator’s console (see disassembly steps 21 and

22).

The following procedures cover sectionalization for

helicopter transportation. The ROPS must be removed

before sectionalization is started, see Volume II.

NOTE

References to the left side, right side, front and

rear are always from the operator’s viewpoint.

DISASSEMBLY

A minimum of two people is required to accomplish

these procedures. Disassembly must be accomplished

on a firm, level surface. One person working on each

side of the machine will expedite disassembly.

NOTE

Whenever possible, return hardware, clamps,

etc. to the holes from which they were

removed. Be sure to tighten them enough so

that they will not loosen from vibration.

1.

Start the engine and center the blade tip and

side shift cylinders. Position the blade at 900 to

the frame and lower the blade to the ground.

Apply a small amount of blade down pressure to

reduce front weight on the articulation joint. Stop

the engine.

2.

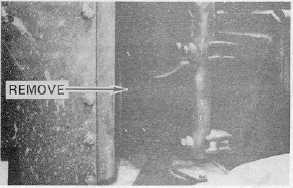

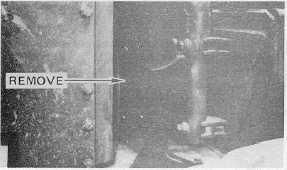

Remove the two pump drive shaft guard halves.

3.

Remove the pump drive shaft.

4.

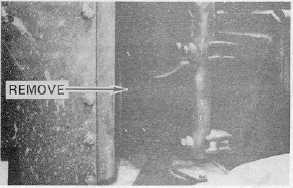

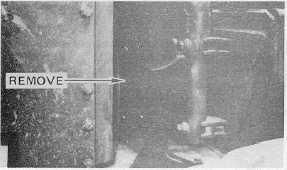

Remove the four (4) outer bolts from the top of

the upper pivot pin.

100