TM 5-3805-263-14&P-3

DISASSEMBLY AND ASSEMBLY

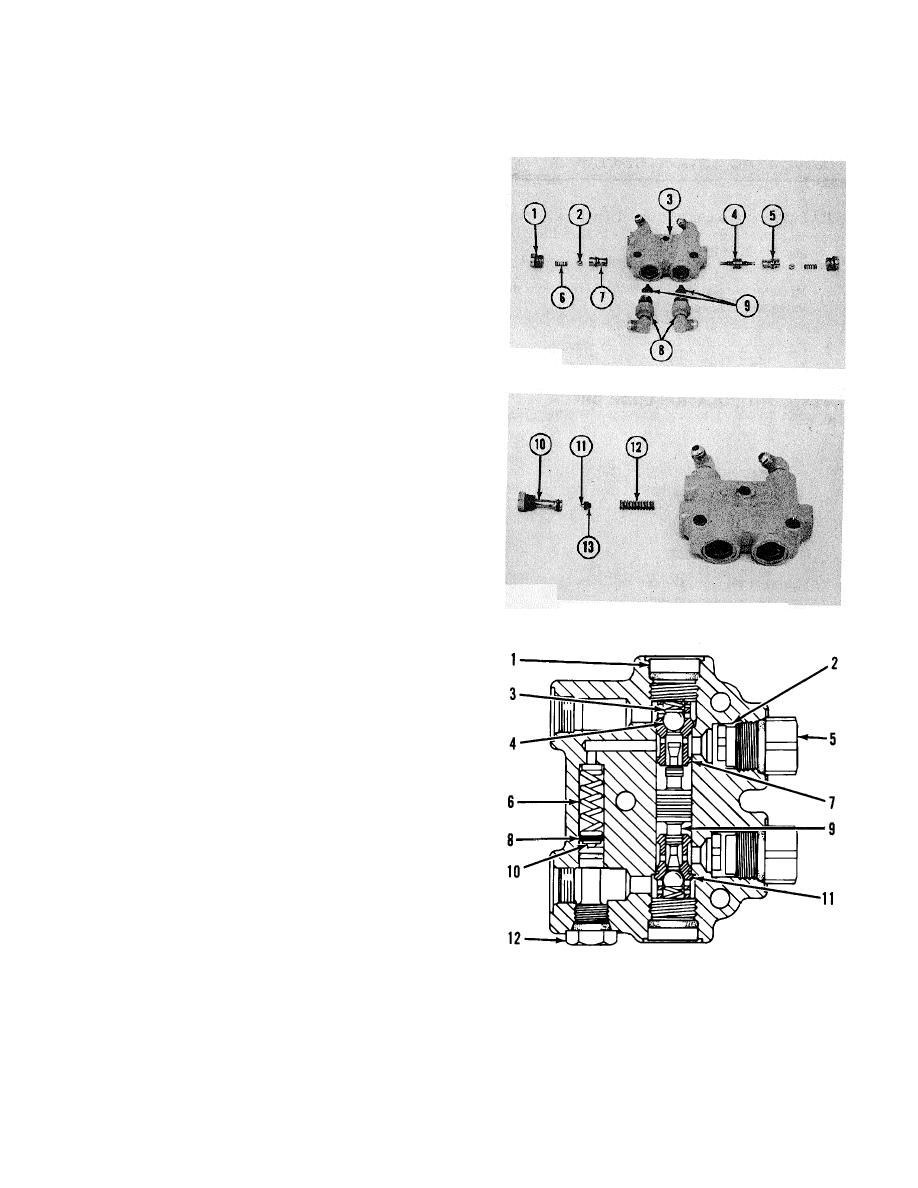

BLADE LIFT LOCK CHECK AND RELIEF VALVE

AND LOCK CHECK VALVES

DISASSEMBLE BLADE LIFT LOCK CHECK AND

RELIEF VALVE AND LOCK CHECK VALVES

start by:

a) remove blade lift lock check and relic valve

b) remove blade sideshift, blade tip, circle drive,

wheel lean, articulation, blade lift or centershift

lock check valve

1. Remove adapters (8) and chokes (9) from body

(3). Remove the O-ring seals from the adapters

NOTE: Only the blade lift lock check and relief valve and

the articulation, blade lift and centershift lock check

valves are equipped with adapters and chokes.

TYPICAL EXAMPLE

2. Remove plug (I), spring (6) and ball (2) fror end of

the body. Remove the O-ring seals from the plugs.

3. Remove piston (4) and seat (5) with a .25 in.

(6.mm) diameter brass rod and a hammer.

Remove seat (7) with a .69 in. (17.5 mm) diameter

bras rod and a hammer.

CAUTION

Be extra careful not to cause damage to the piston

and the seats during disassembly of the valve.

4. Remove plug (10), valve (11), shims (13) and

spring (12) from the body (blade lift lock check and

relief valve only).

ASSEMBLE BLADE LIFT LOCK CHECK AND RELIEF

BLADE LIFT LOCK CHECK

VALVE AND LOCK CHECK VALVES

AND RELIEF VALVE

CAUTION

Be extra careful not to cause damage to the piston

and the seat, during disassembly of the valve.

1. Install seat (I 1) in the body with a .69 in. (17.5

mm) diameter rod and a hammer. Install piston (9)

in the body and seat (11). Install seat (7) in the

body with a .69 in. (17.5 mm) diameter rod and a

hammer. Check to see that the piston falls freely

through the seat. Check both ends of the piston.

2. Install new O-ring seals on the plugs. Install ball

(4), spring (3) and plug (1) in each end o the valve.

Tighten the plugs to a torque of 55 + 5 lb.ft. (75 + 7

N.m).

3. Install new O-ring seals on the adapters. Install

chokes (2) and adapters (5) in the body Tighten

the adapters to a torque of 55 + 5 lb.ft (75 + 7

N.m).

NOTE: Only the blade lift lock check and relief valve and

the articulation, blade lift and the centershift lock check

end by:

valves are equipped with adapters and chokes.

a) install blade lift lock check and relief valve.

4. Install spring (6), shims (8), valve (10) and plug

b) install blade sideshift, blade tip, circle drive,

(12) in the body (blade lift lock check and relief

wheel lean,blade lift, articulation or centershift

valve only).

lock check valve.

3-164