TM 5-3805-263-14&P-3

VEHICLE SYSTEMS

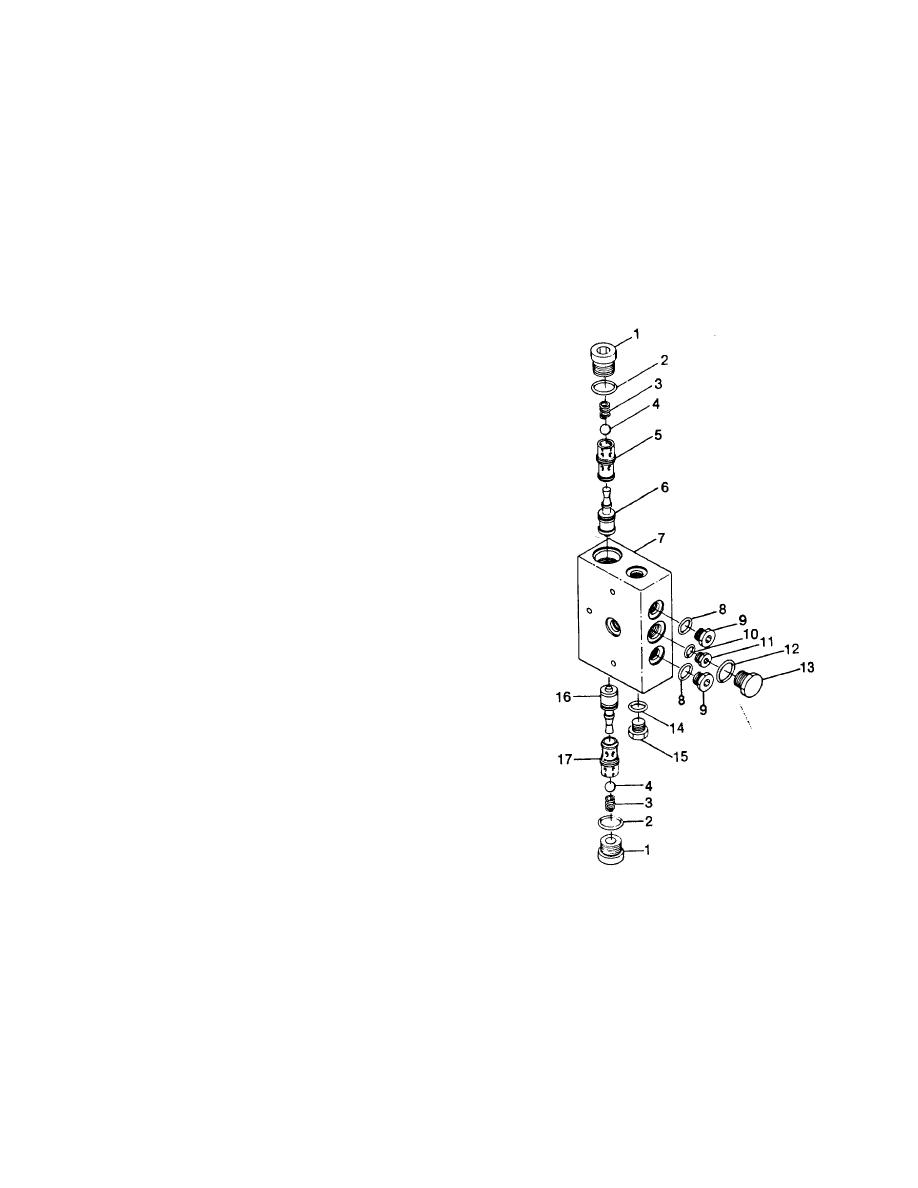

BLADE FLOAT CHECK VALVE

DISASSEMBLY BLADE FLOAT CHECK VALVE

2. Install new "O" ring seals on plugs (1). Install a ball

(4), spring (3) and plug (1) in each end of the

start by:

valve. Tighten the plugs to a torque of 25 + 2 lb. ft.

(34 + 3 N.m).

a) remove blade float check valve

3. Install new "0" ring seals on plugs (9), (13) and

(15). Install the plugs in body (7).

1. Remove plug (1), spring (3) and ball (4) from both

ends of body (7). Remove the "O" ring seals (2)

end by:

from plugs (1).

2. Remove plugs (9) and plug (13) and (15) from the

a) install blade float check valve.

valve body (7). Remove the "O" ring seals from the

plugs.

3. Remove plug (11) from inside of body (7).

Remove "O" ring seal (10) from the plug.

4. Remove piston (6) and seat (5) with a .25 in. (6.4

mm) diameter brass rod and a hammer. Remove

seat (16) and piston (17) with a .69 in. (17.5 mm)

diameter brass rod and a hammer.

CAUTION

Be extra careful not to cause damage

to the piston and the seats during

disassembly of the valve.

ASSEMBLY BLADE FLOAT CHECK VALVE

CAUTION

Be extra careful not to cause damage

to the piston and the seats during

assembly of the valve. Seats are to be

shrunk by means of reduced

temperature before Inserting into

bore.

1. Install seat (16) in body (7) with a .69 in. (17.5 mm)

diameter rod and a hammer. Position pistons (6)

and (16) in body (7). Install seat (5) in the body

with a .69 in. (17.5 mm) diameter rod and a

hammer. Check to see that the pistons fall freely

through the seats.

3-163