TM 5-3805-261-34

REAR AXLE MAINTENANCE.

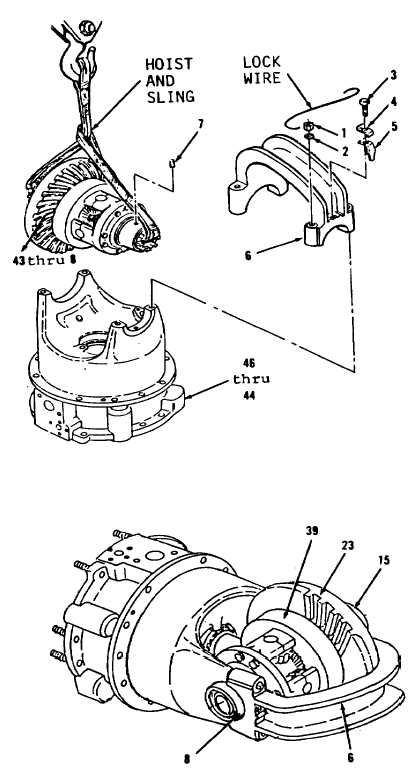

14-17. Differential Assembly. (Sheet 11 of 12)

INSTALLATION

1.

Attach hoist and sling to items

43 thru 8 as an assembly (Figure

14-121).

2.

Position items 43 thru 8 as an

assembly in items 46 thru 44 as

an assembly so that opening in

cage alines with ring (45) and

seal (45) in carrier assembly

(46).

3.

Remove hoist and sling.

4.

Install dowel (7) and cap (6).

5.

Install four washers (2) and nuts

(1). Tighten four nuts (1) to 75

ft-lb torque. Do not install two

bolts (3) and locks (4 and 5) at

this point.

6.

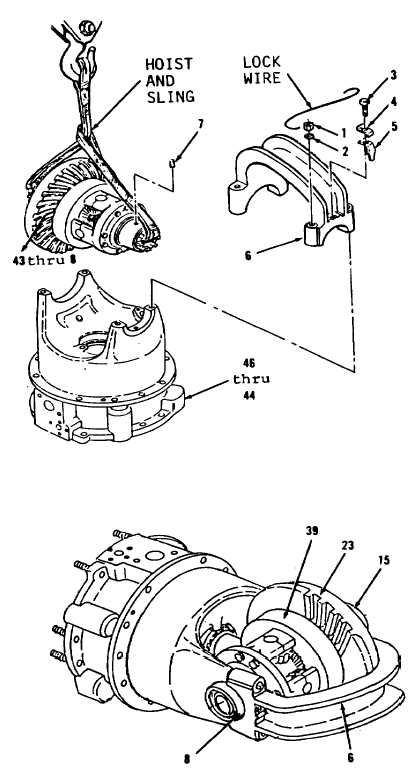

Position differential assembly

(Figure 14-135).

7.

Attach dial scale indicator on

cap (6) so indicator contacts any

tooth on gear (39). Turn gear

and measure backlash, which

should be 0.005 to 0.012 inch.

8.

Using spanner wrench, adjust nut

(23) to obtain 0.005 to 0.012

inch backlash. Nut (8) should be

kept finger tight against top

bearing during adjustment

procedure.

9.

Loosen nut (8) and tighten by

hand to remove end play.

10. While tightening nut (8) 1 to

1-1/2 notches, use dial scale

indicator and measure change in

dimension from end of housing

(15) to cap (6). Dimension must

change by 0.003 to 0.007 inch.

Figure 14-121.

Figure 14-135.

Go to Sheet 12

14-99