TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE.

10-4.

Pump Assembly. (Sheet 17 of 23)

ASSEMBLY

32.

Using feeler gage, measure

clearance between plate (128) and

nine pistons (127). Add or

remove shim(s) (125 and 124)

until a clearance of 0.003 inch

is obtained.

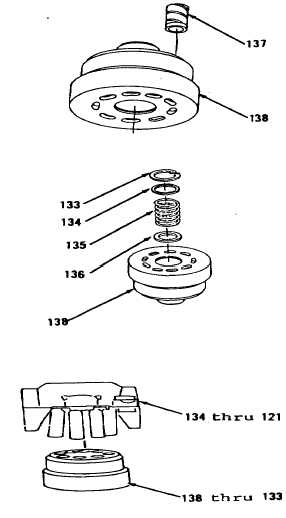

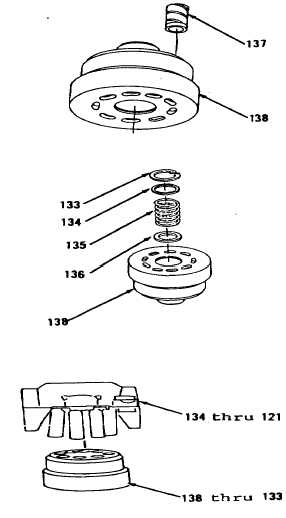

33.

Install nine bearings (137) in

barrel (138, Figure 10-44).

34.

Using protective plate and arbor

press, install spacer (136),

spring (135), spacer (134) and

ring (133) on barrel (138, Figure

10-43).

35.

Position items 138 thru 133 as an

assembly (Figure 10-41) on block.

36.

Install items 134 thru 121 as an

assembly in items 138 thru 133 as

an assembly.

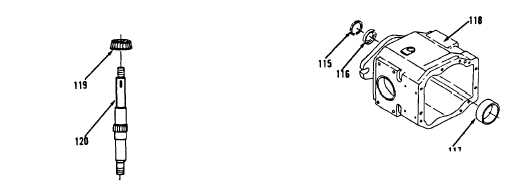

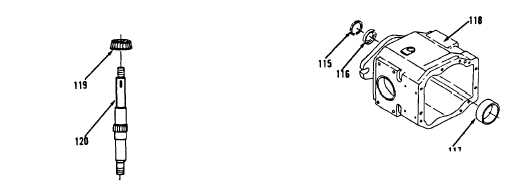

37.

Heat bearing (119) in oil to a

maximum temperature of 275

degrees F and install on shaft

(120, Figure 10-40).

38.

Install bearing cup (117), new

seal (116) and ring (115) in body

(118, Figure 10-38).

Go to Sheet 18

Figure 10-44.

Figure 10-43.

Figure 10-41.

Figure 10-38.

Figure 10-40.

10-31