TM 5-3805-261-34

HYDRAULIC SYSTEM MAINTENANCE. (cont)

10-4.

Pump Assembly. (Sheet 16 of 23)

ASSEMBLY (cont)

24.

Tighten nut (108) to 125 ft-lb

torque.

25.

Move swashplate (132) until

contact with bolt (106) is made.

26.

Adjust bolt (106) for minimum

swashplate (132) angle. Install

the depth gage over the small

angle side of the stop angle bar.

Measure the distances from both

holes as in step 23 from the top

of the gage bar to the smallest

angle of the stop angle bar.

Adjust bolt (106) until the

distances are the same.

27.

Tighten nut (105) to 125 ft-lb

torque.

28.

Remove depth gage, gage bar and

stop angle bar.

NOTE

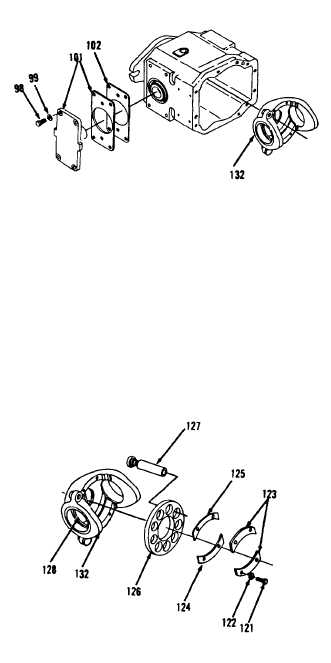

Shim(s) must be kept with the

cover they were removed with.

29.

Remove eight bolts (98), washers

(99), two covers (100) and

shim(s) (101 and 102, Figure

10-55).

30.

Remove swashplate (132).

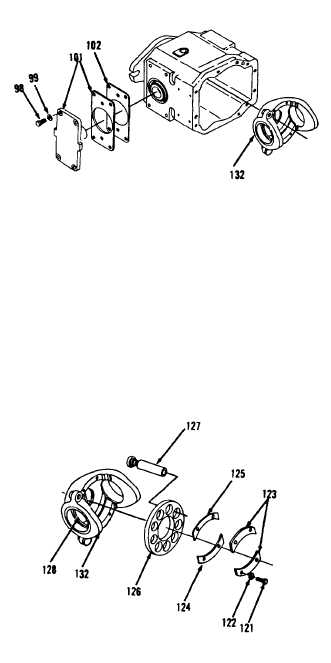

31.

Install nine pistons (127), plate

(126), shim(s) (125 and 124), two

bearings (123), four washers

(122) and bolts (121) in

swashplate (132, Figure 10-56).

Tighten four bolts (121) to 100

lb-in torque.

Go to Sheet 17

Figure 10-55.

Figure 10-56.

10-30