TM 5-3805-261-34

FRONT AXLE MAINTENANCE. (cont)

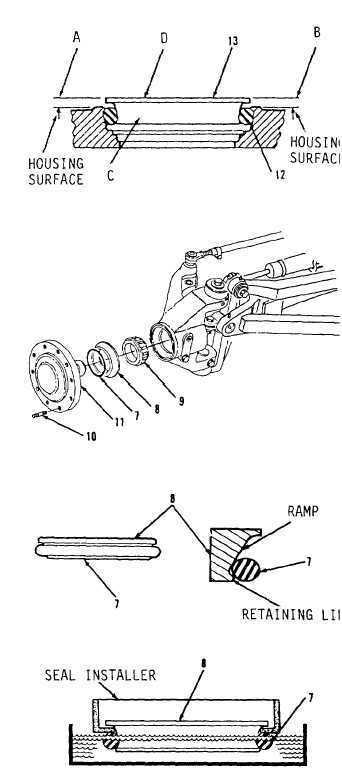

5-15. Wheel Spindle, Bearings and Seals. (Sheet 5 of 7)

INSTALLATION (cont)

9.

Adjust seal (13) and ring (12),

if necessary, using a seal

installer.

10.

Clean seal (13) mating surface

with a lint free cloth. If any

dirt particles remain on seal

face, seal (13) will leak.

11.

Lubricate mating surface of seal

(13) with gear lubricant.

12.

Inspect ring (12) for twists or

bulges. Incorrect installation

will result in seal (13) failure.

If incorrect installation is

obvious, repeat step 6.

13.

Install ten studs (10) on spindle

(11, Figure 5-86). Tighten ten

studs (10) to 170 ft-lb torque.

14.

Heat bearing (9) to 275 degrees F

and install on spindle (11).

15.

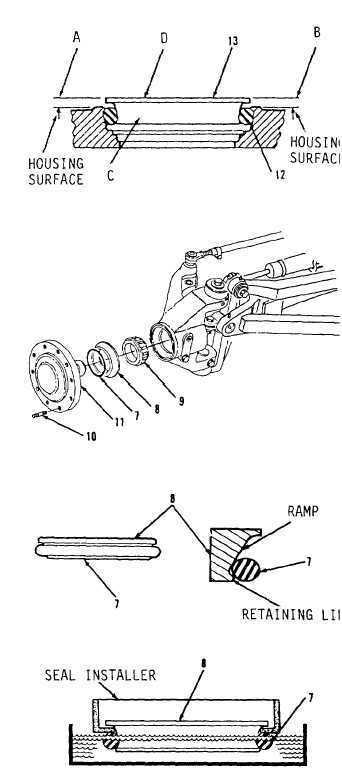

Install ring (7) on seal (8,

Figure 5-92). Make sure ring (7)

is not twisted and is properly

seated on bottom of seal (8) ramp

and against retaining lip.

16.

Install seal installer on seal

(8) and ring (7, Figure 5-93).

17.

Using a seal installer, lower

seal (8) and ring (7) into

container of Tricloroethane until

ring (7) is completely wet.

Figure 5-91.

Figure 5-86.

Figure 5-92.

Figure 5-93.

Go to Sheet 5

5-72