TM 5-3805-261-34

FUEL SYSTEM MAINTENANCE.

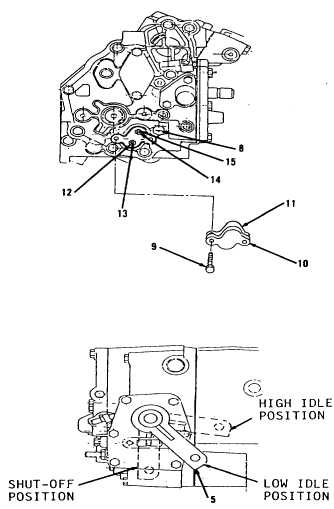

3-27.

Governor and Fuel Injection Pump. (Sheet 9 of 9)

TESTING/ADJUSTING BALANCING POINT

2.

Connect lamp tester to insulator

contact (8, Figure 3-106) and

ground.

3.

Start engine to obtain operating

temperature.

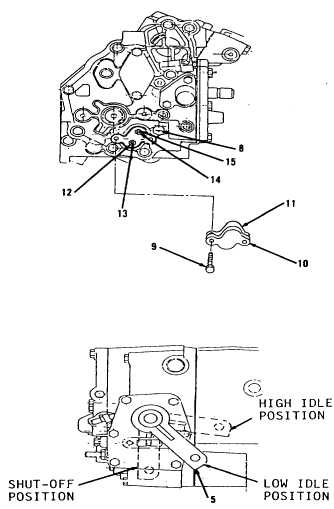

4.

Position governor control lever

(5, Figure 3-107) in high idle.

Record rpm.

5.

Use hydraulic equipment to slowly

add load on engine until lamp

tester lights. Record rpm.

Repeat putting load on engine

several times to verify accurate

readings.

6.

Adjust high idle (22,

Figure 3-108) if balance point of

engine is not 2200 rpm. If

adjustment cannot be obtained

through adjusting screw (22),

replace a weak or wrong governor

spring. Remove test equipment.

NOTE

Return 130G Grader to

original equipment condition.

End of Task

Figure 3-107.

Figure 3-106.

3-143