TM 5-3805-261-34

ENGINE MAINTENANCE. (cont)

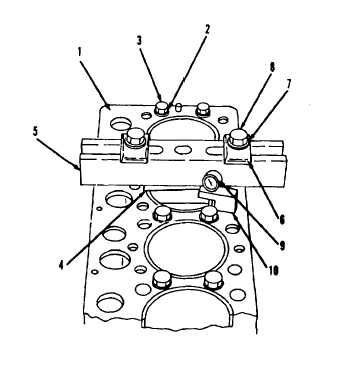

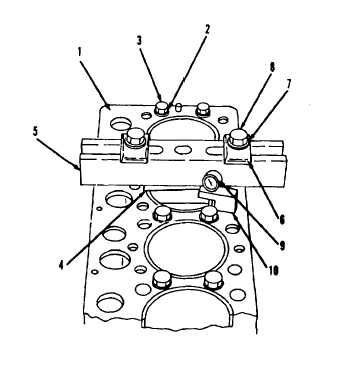

3-8.

Cylinder Block Liners. (Sheet 2 of 3)

INSPECTION

1.

Measure cylinder liner bore.

Maximum allowable diameter is

4.755 inches. If oversized, mark

for removal.

2.

Install spacer plate (1), 20

washers (2) a ten bolts (3,

Figure 3-34) in cylinder block.

Tighten ten bolts (3) evenly in

four steps of 10 ft-lb, 25 ft-lb,

50 ft-lb and 70 ft-lb torque.

Use two of 20 washers (2) with

each of ten bolts (3).

3.

Install adapter plate (4),

crossbar (5), two plates (6),

washers (7) and bolts (8).

Tighten two bolts (8) evenly in

four steps of 5 ft-lb, 15 ft-lb,

25 ft-lb and 50 ft-lb torque.

Measurement from bottom of

crossbar (5) to spacer plate (1)

must be the same on both sides of

cylinder liner.

4.

Assemble contact point, dial

indicator (9) and gage body (10).

5.

Adjust dial indicator (9) to

zero.

6.

Measure cylinder liner projection

as close as possible to four

corners of adapter plate (4) on

cylinder liner. Liner projection

must be 0.0012 to 0.0069 inch.

Difference between four measure-

ments on cylinder liner must not

be more than 0.002 inch.

Difference in average cylinder

liner projection for liners next

to each other must not be more

than 0.002 inch. Maximum

difference in average projection

for all cylinder liners must not

be more than 0.004 inch.

Go to Sheet 3

Figure 3-34.

3-48