TM 5-3805-293-23-3

0075

INSTALLATION CONTINUED

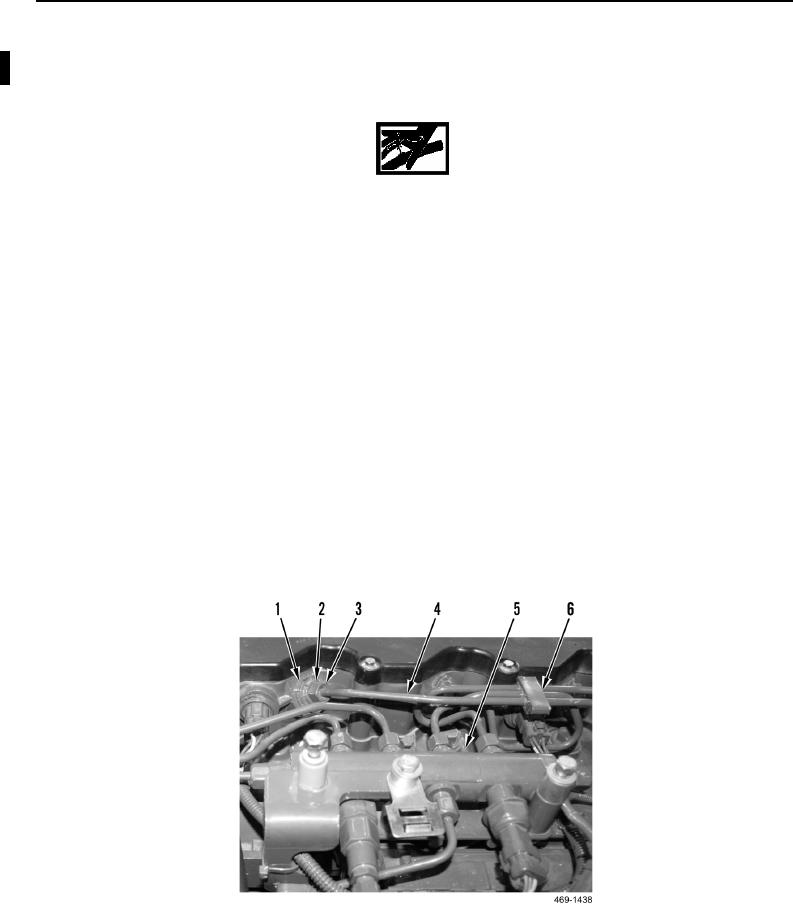

5. Install cylinder sleeve (Figure 9, Item 2) on fuel injector (Figure 9, Item 1). Ensure that flange of seal is flush

with valve mechanism cover base.

WARN I N G

Replace any high-pressure fuel line that is loosened or removed. The fuel system

operates under extreme pressure. High-pressure fuel lines that have been loosened and

retorqued are prone to failure. Failure to follow this warning may result in injury or death to

personnel.

C AU T I O N

Ensure the ends of the fuel injector line are seated in the fuel injector and fuel manifold.

Failure to follow this caution may result in damage to equipment.

N OT E

Install lines as tagged during removal.

6. Install new seal (Figure 9, Item 3) and new high-pressure fuel injector line (Figure 9, Item 4) on fuel injector

(Figure 9, Item 1). Tighten line finger tight.

7. Use T40 torx socket to tighten fuel injector clamp torx screw to 20 lb-ft (27 Nm).

8. Install new high-pressure fuel injector line (Figure 9, Item 4) on fuel rail (Figure 9, Item 5). Tighten to 22 lb-ft

(30 Nm).

9. Tighten high-pressure fuel injector line (Figure 9, Item 4) to 22 lb-ft (30 Nm).

10. Install clip (Figure 9, Item 6) on high-pressure fuel injector lines (Figure 9, Item 4).

Figure 9. Fuel Injector Fuel Line.

075

Change 1