TM 5-3805-293-23-2

0025

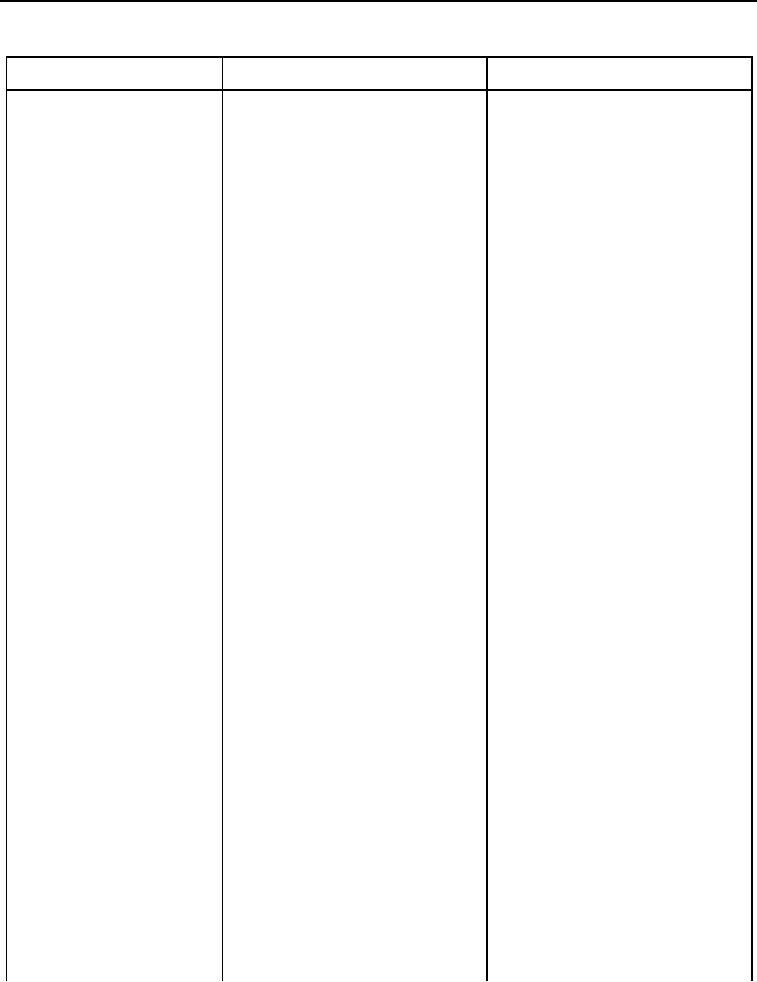

Table 1. Implement Troubleshooting Procedures.

0025

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Implement Circuits are

1. Inspect hydraulic oil for correct

Oil Level OK - Proceed to step 2.

Too Slow

level and type (LO 5-3805-293-

Oil Level Low - Drain and refill

13).

hydraulic tank (LO 5-3805-293-13)

and perform oil configuration (WP

0217).

Oil Incorrect for Operating

Conditions - Drain and refill

hydraulic tank (WP 0217) and

replace hydraulic filter (WP 0208).

Perform oil configuration (WP 0217).

2. Perform Margin Pressure Adjust-

Pressure Cannot Be Adjusted or

ment (WP 0044).

Remains Low - Replace implement

steering pump control valve (WP

0121).

Pressure OK - Proceed to step 3.

3. Start and run machine (TM 5-

3805-293-10) to verify malfunc-

tion has been corrected.

2. Performance of All

1. Inspect hydraulic oil for correct

Oil Level OK - Proceed to step 2.

Implements Are Erratic

level (LO 5-3805-293-13).

Oil Level Low - Drain and refill

hydraulic tank (LO 5-3805-293-13)

and perform oil configuration (WP

0217).

2. Start machine, and monitor

hydraulic oil temperature using

the messenger (TM 5-3805-293-

10) until hydraulic oil reaches at

least 104 degrees F (40 degrees

C).

Performance of All Implements

3. Operate the blade lift, blade side

Remain Erratic - Proceed to step 4.

shift, blade tip, scarifier, and cen-

ter shift (TM 5-3805-293-10) to

Performance of Implements OK -

allow air to bleed from system.

Proceed to step 6.

4. Perform Margin Pressure Adjust-

Pressure Cannot Be Adjusted or

Remains Low - Replace implement

ment (WP 0044).

steering pump control valve (WP

0121), proceed to step 6.

Pressure OK - proceed to step 5.