POWER TRAIN

DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-2

FINAL DRIVES

6.

7.

8.

9.

10.

11.

12.

13.

14.

2-60

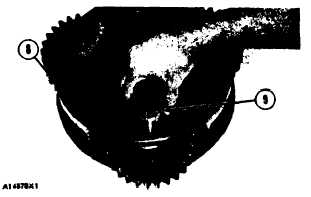

Install the washer in the carrier. Install the

large retaining ring that holds the washer

with tool (B).

Install the rollers in the gears. Install the

gears and the washers in planet carrier (8).

Install shafts (9) that hold the gears in the

planet carrier. Install the retainers, the bolts

and the locks that hold the retainers. Bend

the locks against the bolts.

Put the carrier on its other end. Fasten a

hoist to the carrier. Put planet carrier (8) in

position on shaft (6) and in ring gear (2).

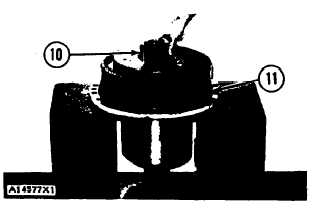

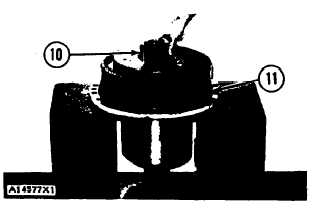

Install pinion (10) in the planet carrier.

Install a wire to hold the planet carrier in

position in the housing.

Install O-ring seal (11) on the housing.

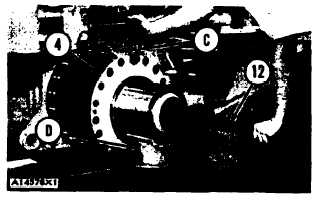

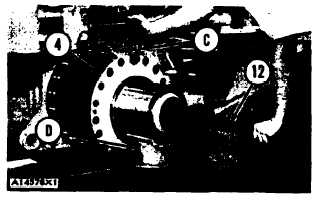

Install tooling (C) on housing (4). Fasten a

hoist to tooling (C). Lift housing (4) and

put it in position on tooling (D) and a floor

jack. Put axle (12) in position in the

housing to help keep the housing in balance.

Move the final drive housing toward the

bevel gear case. Remove the wire that holds

the planet carrier in the housing. Remove

tooling (C) and the hoist from the housing.

Put the final drive housing in position over

the studs in the bevel gear case. Install the

nuts and the washers that hold it. Remove

tooling (D).

Tighten nuts (13) to a torque of 300 ± 15 lb. ft.

(408 ± 2.0 mkg). If removed, install new seal

(14) into outer housing (17) flush with end. Put

STP OIL TREATMENT or CASITE MOTOR

HONEY on the seal and inner housing surface.

Install tooling (E) on the outer housing.

Fasten a hoist to tooling (E). Put some oil

on the inside surfaces of the oscillation

bearing rings (15) and on the outside

surface of the inner housing. Install rings

(15) in outer housing (17). Install washer

( 16) on the inner housing. Washer (16) is in

three sections. Put some clean grease on the

washer.

Put housing (17) in position on the inner

housing. Rings ( 15) and housing (17) can be

moved with a soft hammer if necessary.

Remove tooling (E).