DISASSEMBLY AND ASSEMBLY

TM 5-3805-263-14&P-2

CRANKSHAFT AND GEAR

CAUTION

Make sure part number on cap is toward front

of engine, and number on bottom of cap is the

same as number on block when caps are in-

stalled.

5.

6.

7.

8.

9.

10.

11.

Clean the Nos. 2, 3 and 4 main bearing caps.

Install new bearings in the caps. Put clean en-

gine oil on the bearings, bolts, threads and sur-

faces of the washers for the caps.

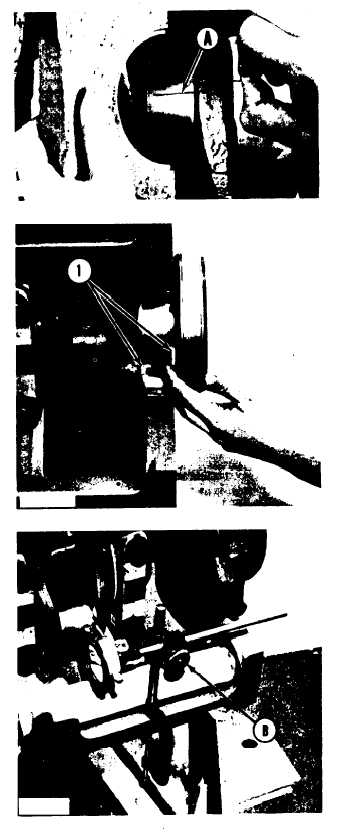

Check the bearing clearance with Plastigage

(A). Install the caps and tighten the bolts to a

torque of 41 ± 4 N·m (30 ± 3 lb.ft.). Put a

mark on each bolt head and the bearing caps.

Tighten the bolts 90° more. Remove the bear-

ing caps and measure the width of the Plasti-

gage. The main bearing clearance (Plastigage

width) with new bearings must be 0.076 to

0.165 mm (.0030 to .0065 in.). The maximum

permissible clearance with used bearings is

0.25 mm (.010 in.).

Put the caps in position on the engine and in-

stall the washers and bolts. Tighten the bolts to

a torque of 41 ± 4 N·m (30 ± 3 lb.ft.). Put a

mark on each bolt head and the bearing caps.

Tighten the bolts 90° more.

Remove the Nos. 1 and 5 main bearing caps.

Follow the procedure in Steps 5 and 6 and

check the main bearing clearance for the Nos. 1

and 5 main bearings.

Follow the procedure in Step 7 and install the

No. 1 main bearing cap.

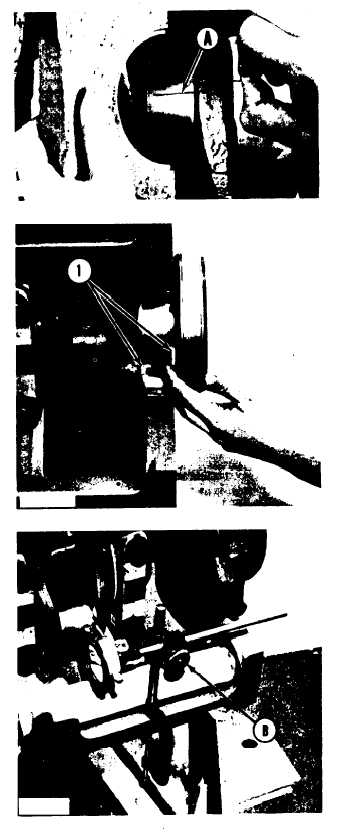

Put clean engine oil on thrust bearings (1).

Install the bearings with the steel back against

the cylinder block. Install the No. 5 main bear-

ing cap. Tighten the bolts for the cap with the

procedure in Step 7.

Check the crankshaft end play with tool group

(B). The end play is controlled by the thrust

bearings on the No. 5 main. The end play with

new bearings must be 0.064 to 0.368 mm

(.0025 to .0145 in.). The maximum permissible

end play with used bearings is 0.64 mm (.025

in.).

NOTE: If a replacement has been made for any of

the timing gears, it will be necessary to check the

engine timing to make sure it is correct. See IN-

STALL FUEL INJECTION PUMP HOUSING

AND GOVERNOR.

end by:

a) install pistons

b) install timing gear cover

c) install hydraulic pump gear train

1-217